Factory selling Niigata 450t All-electric used Injection Molding Machine for Burundi Importers

Factory selling Niigata 450t All-electric used Injection Molding Machine for Burundi Importers Detail:

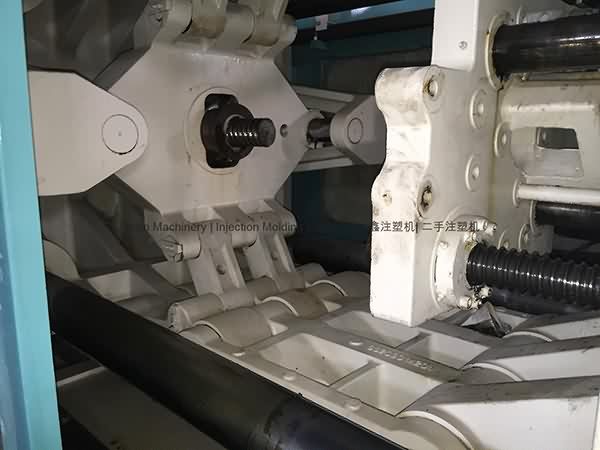

Niigata 450t All-Electric used Injection Molding Machine

Youtube Video: https://youtu.be/wHoMpY6lKng

Model: MD450S-IV.

Year: 2007.

Screw diameter: 82mm.

Tie bar spacing:820x820mm.

Injection Speed: 150mm/s.

Two units available. Interested customer is welcome to visit our warehouse to test machines running. Our warehouse is at Shenzhen, China (very near Hongkong and Guanzhou) .

Visit us after Chinaplas or Canton Fair!

Daxin Machinery

-Over 200 units of used injection molding machines in stock

-All can be inspected in the same warehouse under one roof

-All can be powered on for test-run in working condition

sales@daxin88.com / daxin88@hotmail.com

Skype: daxin-machinery / www.daxin88.com

Mobile: +8613509620296 (whatsapp) / +6596479097 (WeChat)

Follow Daxin Machinery: Facebook, Twitter, Google+, LinkedIn, Youtube.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Emergence of Injection Molding in Plastic Industry

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" plus the theory of "quality the basic, have faith in the main and management the advanced" for Factory selling Niigata 450t All-electric used Injection Molding Machine for Burundi Importers, The product will supply to all over the world, such as: Paraguay , New Zealand , Bangladesh , More than 26 years, Professional companies from all over the world take us as their long-term and stable partners. We are keeping durable business relationship with more than 200 wholesalers in Japan, Korea, USA, UK, Germany, Canada, France, Italian, Poland, South Africa, Ghana, Nigeria etc.

It's tailored for the demand of high speed production.

Used Rajoo PP Film Machine. Plastic Film Extruder For Sale In Karnataka

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!