Factory selling Sumitomo 130t All-Electric used Injection Molding Machine to Honduras Factory

Factory selling Sumitomo 130t All-Electric used Injection Molding Machine to Honduras Factory Detail:

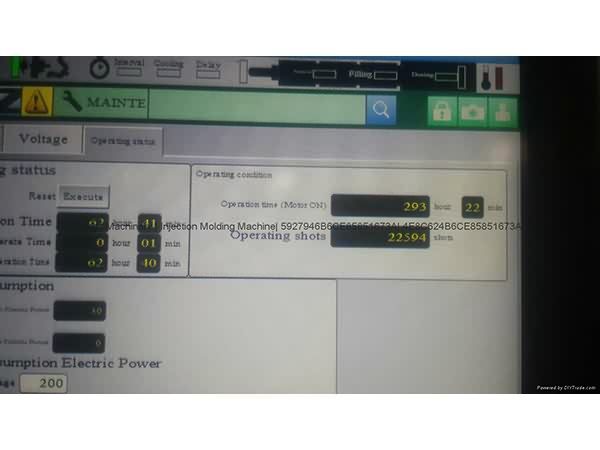

Sumitomo 130t All-Electric Used Injection Molding Machine Video: https://youtu.be/dh8sN_uCzjU Model: SE130EV-C360HP. Year: 2013. Screw diameter: 25/28mm. Injection Speed: 1000mm/s. Tie bar spacing: 510x510mm. 3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our enterprise with the long-term to build with each other with consumers for mutual reciprocity and mutual advantage for Factory selling Sumitomo 130t All-Electric used Injection Molding Machine to Honduras Factory, The product will supply to all over the world, such as: Qatar , Croatia , Houston , "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, please feel free to contact us. We hope to establish cooperative relationships with you in the near future.

Double Shot injection or 2K moulding is referring to injection 2 material at the same time. This technique will help to save some assembly jobs.

Matt Pearce beats Mould for the first time and claims the Northern Masters.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.