Factory source Chen Hsong Super Master SM50 used Injection Molding Machine – Servo Plastic Injection Moulding Machine

Factory source Chen Hsong Super Master SM50 used Injection Molding Machine – Servo Plastic Injection Moulding Machine Detail:

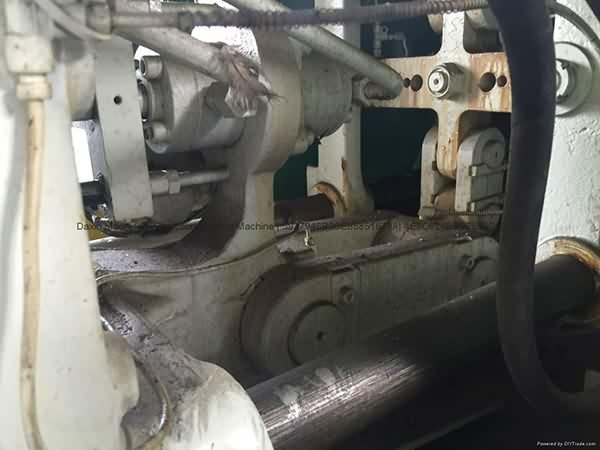

Chen Hsong Super Master 50t Used Injection Molding Machine.

Model: SM50T.

Year: 2004.

Screw diameter: 24mm.

Tie bar spacing: 310x310mm.

Controller: 2000.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Plastic Injection Molding: Past, Present and Future

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for Factory source Chen Hsong Super Master SM50 used Injection Molding Machine – Servo Plastic Injection Moulding Machine, The product will supply to all over the world, such as: Argentina , Haiti , Suriname , We are introduced as a one of the growing manufacture supplier and export of our products. We have a team of dedicated trained professional who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

Automatic blow molding machine for making plastic balls!

Full auto deflashing with conveyor

ball Production per hour 3000 pcs

Screw 75mm, parison controller available

Know more details, please contact:

Mr Ken (Export Manager)

Co: Dawson Machinery & Mould Group Co.,Ltd

Zhangjiagang Apollo Machinery Co.Ltd

Add: TianZhuang Of FengHuang Town,Zhangjiagang

City,JiangSu Province,China

Tel: 0086-512-58990369 Mob: 0086-13913143237

Skype: t542892865

MSN: kenmartin2009@hotmail.com

E-mail: kenmartin520@gmail.com

Yahoo: kenmartin2003@yahoo.com

Website: www.dawson-plastic.com

pvc braided hose extrusion machine line weifang jingda plastic machinery co.,

Weifang Jingda Plastic Machinery Co.,Ltd

Add:Changle, Weifang, Shandong, China

https://www.hoseextruder.com

Email: info@hoseextruder.com

Mobile/WhatsApp/Viber: 008615715362527

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.