Factory supplied JSWJ280EIII used Injection Molding Machine for Netherlands Manufacturers

Factory supplied JSWJ280EIII used Injection Molding Machine for Netherlands Manufacturers Detail:

JSWJ280EIII used Injection Molding Machine for sale.

Model: J280EIII.

Year : 2005.

Tie bar spacing: 630x630mm.

Screw diameter: 53mm.

Injection Volume: 463cm^3.

Video: https://youtu.be/eaAHtdSJ9GQ

Good running condition. Interested customer is welcome to visit our warehouse to inspect and test machine running.

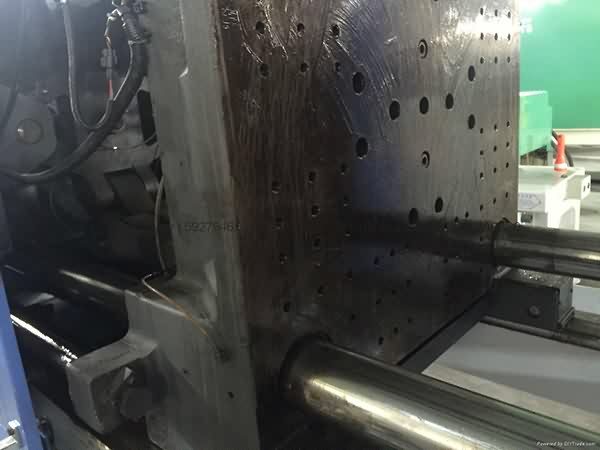

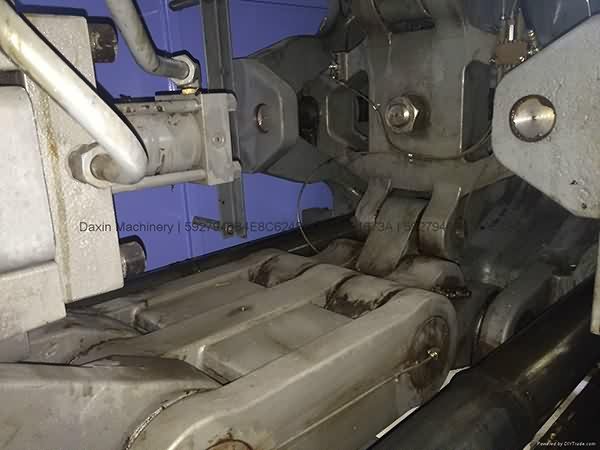

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Plastic Injection Molding: Past, Present and Future

To create more value for customers is our business philosophy; customer growing is our working chase for Factory supplied JSWJ280EIII used Injection Molding Machine for Netherlands Manufacturers, The product will supply to all over the world, such as: European , Greenland , Japan , We have a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment.

Woojin Plaimm PR Film

https://www.sumitomo-shi-demag.eu

In this application you see how simple Automation can be. A very small 50t machine with an infrared camera Control System. Additional to that you see a servo picker for the sprues and a chute directly integrated into the machine housing. The sprues are regranulated and recylced into the process.

Our other social media channels:

https://www.linkedin.com/company/sumitomo-shi-demag

https://www.facebook.com/sumitomoshidemag/

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!