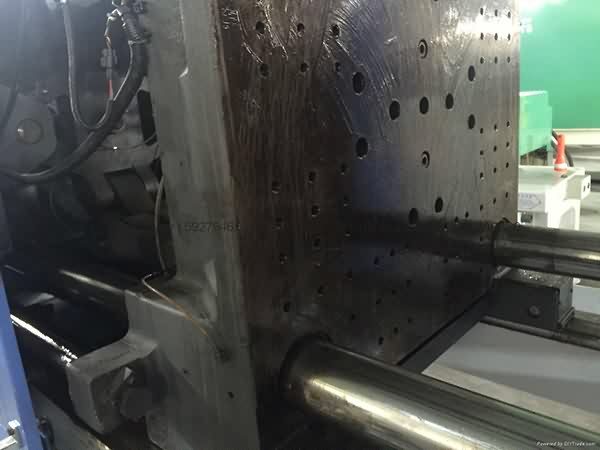

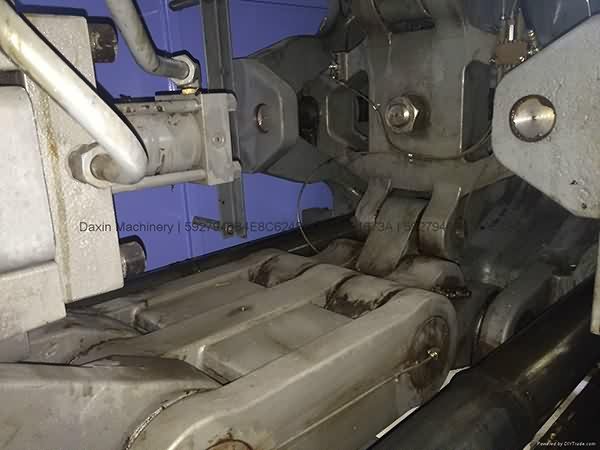

Factory supplied JSWJ280EIII used Injection Molding Machine for Peru Importers

Factory supplied JSWJ280EIII used Injection Molding Machine for Peru Importers Detail:

JSWJ280EIII used Injection Molding Machine for sale.

Model: J280EIII.

Year : 2005.

Tie bar spacing: 630x630mm.

Screw diameter: 53mm.

Injection Volume: 463cm^3.

Video: https://youtu.be/eaAHtdSJ9GQ

Good running condition. Interested customer is welcome to visit our warehouse to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

How Importers And Exporters Can Benefit From The Canton Fair

Often customer-oriented, and it's our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for Factory supplied JSWJ280EIII used Injection Molding Machine for Peru Importers, The product will supply to all over the world, such as: Sevilla , The Swiss , Lithuania , With excellent products, high quality service and sincere attitude of service, we ensure customer satisfaction and help customers create value for mutual benefit and create a win-win situation. Welcome customers all over the world to contact us or visit our company. We will satisfy you with our professional service!

For full details of this machine, please visit our website at www.stvmachinery.co.uk.

Yizumi machines are now available in the UK and EIRE, supported by STV Machinery. We have a showroom available for inspection of the machines.

We also offer refurbished injection moulding machines from all manufacturers. There are not many places customers can directly compare new machines with older refurbished equipment. Come and take a look!

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.