Factory supplied Nanrong 120t used Injection Molding Machine Supply to Johor

Factory supplied Nanrong 120t used Injection Molding Machine Supply to Johor Detail:

Taiwan Nanrong 120t Used Plastic Injection Molding Machine

Youtube Video: https://youtu.be/Dpld0N3LLpk

Model: 120SA

Tonnage: 120t

Screw diameter: 22mm

Tie bar spacing: 360x360mm

Year: 2006

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou.Interested customers can visit us after Chinaplas to power on machines for test-run.

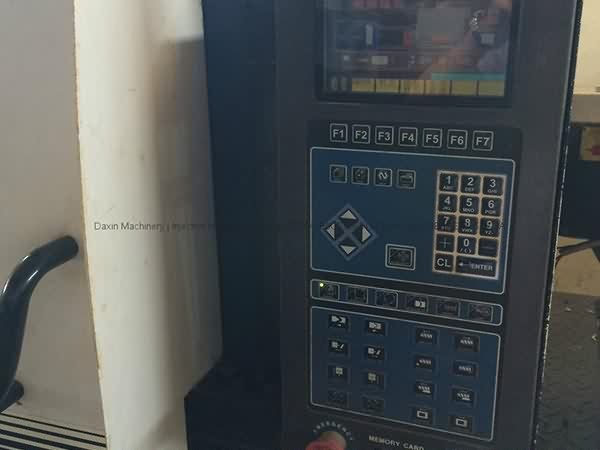

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

Our enterprise insists all along the standard policy of "product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as consistent purpose of "reputation first, client first" for Factory supplied Nanrong 120t used Injection Molding Machine Supply to Johor, The product will supply to all over the world, such as: Atlanta , Montpellier , Italy , As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

20,000Lb Used Taylor Forklifts For Sale 616-200-4308 for more information go to https://d1a6prx2duc1gy.cloudfront.net/ or phone us at (616) 200-4308. Available Forklifts changes often, contact us for most recent inventory. Go here: https://d26fito5xtoopf.cloudfront.net We also buy and sell forklifts. Capacities from 15,000lb to 100,000lb for sale.

Used Taylor, 20,000lb, Forklifts For Sale 616-200-4308

https://commondatastorage.googleapis.com/usedmachinery/used-large-capacity-forklifts-sale-fork-trucks/index.html

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!