Factory supplied Toshiba 1300t (wide platen) used Injection Molding Machine Supply to Bahrain

Factory supplied Toshiba 1300t (wide platen) used Injection Molding Machine Supply to Bahrain Detail:

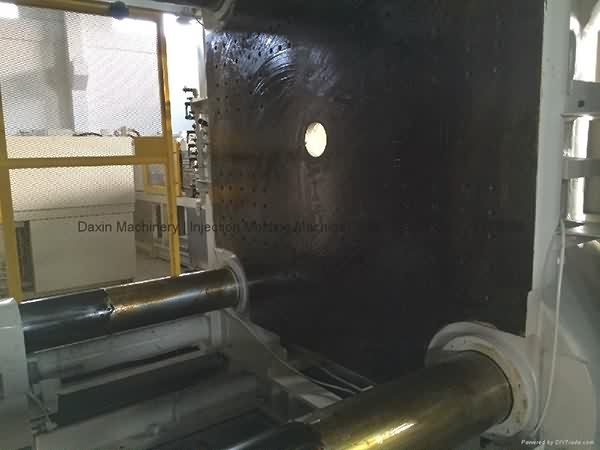

A Toshiba 1300t (wide platen) used injection molding machine for sale.

Model: IS1300DFW-200A.

Year of manufacture: 2004.

Screw diameter: 140mm.

Shot weight:9150g.

Tie bar spacing: 1430x1430mm.

Youtube video: https://youtu.be/hRc5cZvXlFs

Machine has wide platen, it is in good running condition. Interested customer is welcome to visit our warehouse to inspect and test run the machine.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

How Importers And Exporters Can Benefit From The Canton Fair

Our firm since its inception, normally regards item top quality as company life, constantly make improvements to generation technology, improve product excellent and repeatedly strengthen organization total good quality management, in strict accordance with the national standard ISO 9001:2000 for Factory supplied Toshiba 1300t (wide platen) used Injection Molding Machine Supply to Bahrain, The product will supply to all over the world, such as: kazakhstan , Marseille , Mombasa , Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

Hard plastic regrind recycling machine - Model TR-100V Polystar(Taiwan) - Original manufacturer of Hard plastic regrind recycling machine Send your inquiry ...

WE ARE THE BEST PLASTIC MACHINE SUPPLIER: PET semi-automatic stretch blow molding machine Automatic stretch blow moulding machine ...

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.