Factory Supply Nanrong 250t used Injection Molding Machine Wholesale to Adelaide

Factory Supply Nanrong 250t used Injection Molding Machine Wholesale to Adelaide Detail:

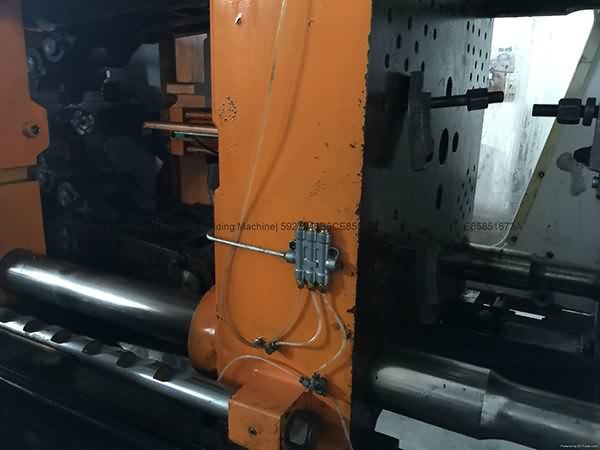

Taiwan Nanrong 250t used Injection Molding Machine.

Model: TNR250S.

Year: 2007 Dec.

Screw diameter: 48mm.

Tie bar spacing: 510x510mm.

Good running condition. Interested customer can visit our warehouse to inspect machine and power on for dry-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Emergence of Injection Molding in Plastic Industry

Our advantages are lower prices,dynamic sales team,specialized QC,strong factories,high quality products and services for Factory Supply Nanrong 250t used Injection Molding Machine Wholesale to Adelaide, The product will supply to all over the world, such as: Nigeria , Romania , Atlanta , Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

SOLD MACHINE

Injection stretch blow moulding machines for PET bottles second hand Brand: NISSEI ASB Model: PF 8-4B Year: 1999

https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300028168?OpenDocument&ln=en&origin=YouTube

Máquina de inyección-soplado para botellas de PET segunda mano Marca: NISSEI ASB Modelo: PF 8-4B Año: 1999

Spritzblasformmaschine Gebrauchtmaschinen,

Souffleuse d'injection Machine d'occasion,

Soffiatrice di iniezione soffiaggio per bottiglie di PET macchina di seconda mano,

бывшее в употреблении оборудование,

Maszyny do produkcji preformy z wydmuchaniem butelki maszyny z drugiej reki,

Enjeksiyon streç şişirme kalıplama makinesi

--Enjeksiyon şişirme makinası

Kullanılmış makine,

Injekció strech flakonfúvó gépek PET-palackok Használt gép,

Vstřikovací protáhnout vyfukovací stroje na PET láhve Použitý Stroj

Huaao Electricity Technology Co.,Ltd is the only supplier who professional produce: APG machine,APG molds,casting mold and instrument transformer winding ...

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.