Factory wholesale JSWJ1600EIII used Injection Molding Machine to Germany Importers

Factory wholesale JSWJ1600EIII used Injection Molding Machine to Germany Importers Detail:

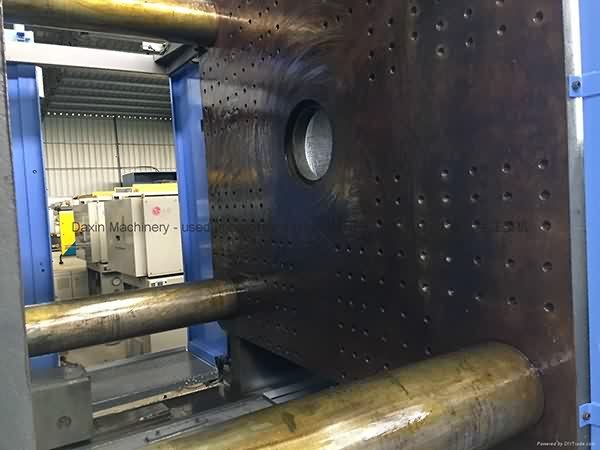

JSW 1600t used injection molding machine.

Model: J1600EIII.

Year: 2008.

Tie bar spacing: 1530x1280mm.

Screw diameter: 140mm.

Machine is in good working condition. Interested customer can visit our warehouse to inspect the machine and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Emergence of Injection Molding in Plastic Industry

We pursue the administration tenet of "Quality is remarkable, Services is supreme, Status is first", and will sincerely create and share success with all customers for Factory wholesale JSWJ1600EIII used Injection Molding Machine to Germany Importers, The product will supply to all over the world, such as: Saudi Arabia , Oslo , Birmingham , Many products fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't need to waste time shopping around.

secadae@hotmail.com , https://www.padprintermachine.com secadae@gmail.com. contacter :Ms Ada China Sumglex Europe corp can customer pad printer machine and silk_screen machine .It is bottle cap automatic machine is manufactured By Sumglex Europe Corp from China/Chinese .

1.full-automatic plastic bottle cap pad printing machine with conveyor (APM-4C-cap) and full-automatic plastic beverage bottle cap or beer bottle cap pad printing machine with Tank columns APM-4TC-cap

Model:APM-4C-cap

Plate size:100*200mm

Printing area:Φ28-30mm Top of caps

Print mode:1、A cycle is complete 8 caps for 4color printing

2、A cycle is complete 16 caps 2color printing

Printing color:4 color /2 color

Products size:Φ28-30mmcaps

Speed:900cycle/hour=900*8=7200pcs/hour 4color

900cycle/hour=900*8*2=14000pcs/hour 2color

Power:Single-phase 220V 50/60HZ 7KW

AIR:6Bar

Machine size:1800*1220*2000mm

Weight:320KG

1.full-automatic plastic bottle cap pad printing machine with conveyor (APM-4C-cap) and full-automatic plastic beverage bottle cap or beer bottle cap pad printing machine with Tank columns APM-4TC-cap

Model:APM-4C-cap

Plate size:100*200mm

Printing area:Φ28-30mm Top of caps

Print mode:1、A cycle is complete 8 caps for 4color printing

2、A cycle is complete 16 caps 2color printing

Printing color:4 color /2 color

Products size:Φ28-30mmcaps

Speed:900cycle/hour=900*8=7200pcs/hour 4color

900cycle/hour=900*8*2=14000pcs/hour 2color

Power:Single-phase 220V 50/60HZ 7KW

AIR:6Bar

Machine size:1800*1220*2000mm

Weight:320KG

JHB 5 Liter jerry can production line with leaking test machine.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.