Factory wholesale Mitsubishi 1300t Used Injection Molding Machine to Kuwait Manufacturer

Factory wholesale Mitsubishi 1300t Used Injection Molding Machine to Kuwait Manufacturer Detail:

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Screw diameter: 100mm.

Injection volume: 4540cm^3.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

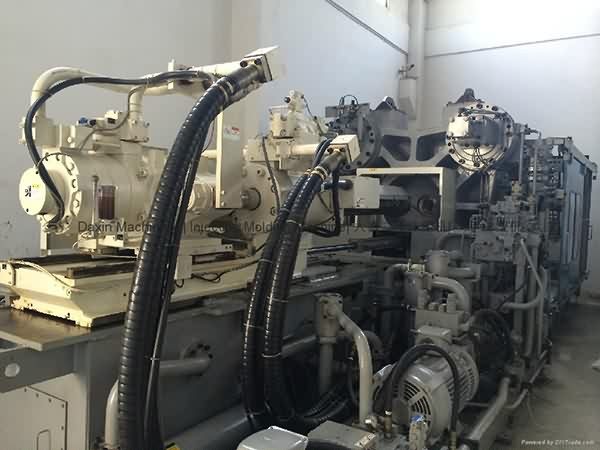

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

We can easily normally satisfy our respected buyers with our excellent high-quality, excellent selling price and good service due to we've been far more expert and more hard-working and do it in cost-effective way for Factory wholesale Mitsubishi 1300t Used Injection Molding Machine to Kuwait Manufacturer, The product will supply to all over the world, such as: Swiss , Ghana , Frankfurt , Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part products. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

Call: 888-803-3412 Used Plastic Machinery For Sale In Pakistan From Plastic Machinery & Parts Searching for used plastic machinery for sale in Pakistan?

https://www.arburg.com - A two-component injection moulding machine ALLROUNDER 902 S with an innovative 32-cavity cube mould produces in just 10 ...

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!