Factory wholesale Niigata 450t All-electric used Injection Molding Machine to Argentina Manufacturers

Factory wholesale Niigata 450t All-electric used Injection Molding Machine to Argentina Manufacturers Detail:

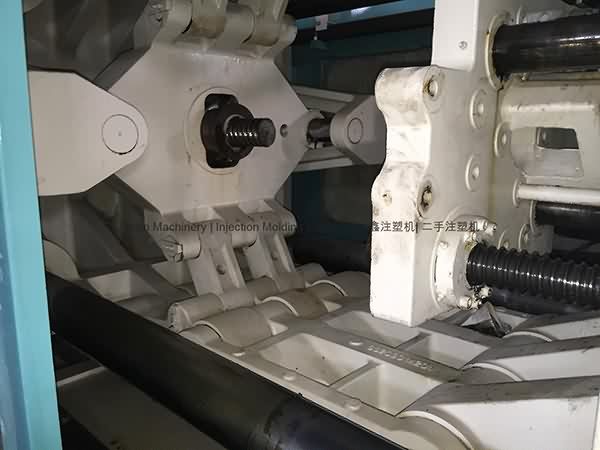

Niigata 450t All-Electric used Injection Molding Machine

Youtube Video: https://youtu.be/wHoMpY6lKng

Model: MD450S-IV.

Year: 2007.

Screw diameter: 82mm.

Tie bar spacing:820x820mm.

Injection Speed: 150mm/s.

Two units available. Interested customer is welcome to visit our warehouse to test machines running. Our warehouse is at Shenzhen, China (very near Hongkong and Guanzhou) .

Visit us after Chinaplas or Canton Fair!

Daxin Machinery

-Over 200 units of used injection molding machines in stock

-All can be inspected in the same warehouse under one roof

-All can be powered on for test-run in working condition

sales@daxin88.com / daxin88@hotmail.com

Skype: daxin-machinery / www.daxin88.com

Mobile: +8613509620296 (whatsapp) / +6596479097 (WeChat)

Follow Daxin Machinery: Facebook, Twitter, Google+, LinkedIn, Youtube.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

To constantly improve the management system by virtue of the rule of "sincerely, good faith and quality are the base of enterprise development", we widely absorb the essence of related products internationally, and constantly develop new products to meet the demands of customers for Factory wholesale Niigata 450t All-electric used Injection Molding Machine to Argentina Manufacturers, The product will supply to all over the world, such as: Uzbekistan , Malta , Morocco , Our products have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we are sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

The Creation Station CNC Router Kickstarter Video

SOLD MACHINE

Injection stretch blow moulding machines for PET bottles second hand Brand: NISSEI ASB Model: PF 8-4B Year: 1999

https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300028168?OpenDocument&ln=en&origin=YouTube

Máquina de inyección-soplado para botellas de PET segunda mano Marca: NISSEI ASB Modelo: PF 8-4B Año: 1999

Spritzblasformmaschine Gebrauchtmaschinen,

Souffleuse d'injection Machine d'occasion,

Soffiatrice di iniezione soffiaggio per bottiglie di PET macchina di seconda mano,

бывшее в употреблении оборудование,

Maszyny do produkcji preformy z wydmuchaniem butelki maszyny z drugiej reki,

Enjeksiyon streç şişirme kalıplama makinesi

--Enjeksiyon şişirme makinası

Kullanılmış makine,

Injekció strech flakonfúvó gépek PET-palackok Használt gép,

Vstřikovací protáhnout vyfukovací stroje na PET láhve Použitý Stroj

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!