Factory wholesale Toshiba IS450GS Used Injection Molding Machine to America Factories

Factory wholesale Toshiba IS450GS Used Injection Molding Machine to America Factories Detail:

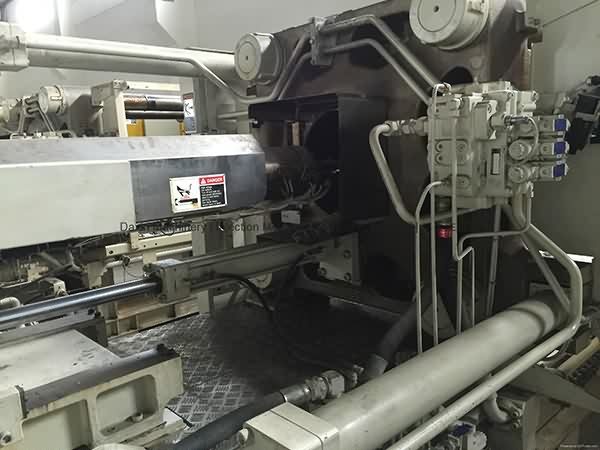

Toshiba 450t used plastic injection molding machine

Youtube: https://youtu.be/WJngGtO1BdI

Model: IS450GS.

Year: 2003.

Screw diameter: 70mm.

Injection weight: 1360g

Tie bar spacing: 810x810mm.

Controller: V10.

A few units for sale. Machines are in good working condition, kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us after Chinaplas to power on the machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Plastic Injection Molding: Past, Present and Future

Our business promises all users of the first-class items and the most satisfying post-sale company. We warmly welcome our regular and new prospects to join us for Factory wholesale Toshiba IS450GS Used Injection Molding Machine to America Factories, The product will supply to all over the world, such as: Bulgaria , Manchester , Ecuador , We firmly think that we have the full capability to present you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

Information about the Dorman Fuel Line Repair Kit, part number 800-300.

Robot taking parts out of Plastics Injection Molding machine. It removes part, degates (cuts) the runner, drops runner on scrap conveyor, then places parts on ...

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!