Factory wholesale Toshiba IS450GS Used Injection Molding Machine to Mozambique Factory

Factory wholesale Toshiba IS450GS Used Injection Molding Machine to Mozambique Factory Detail:

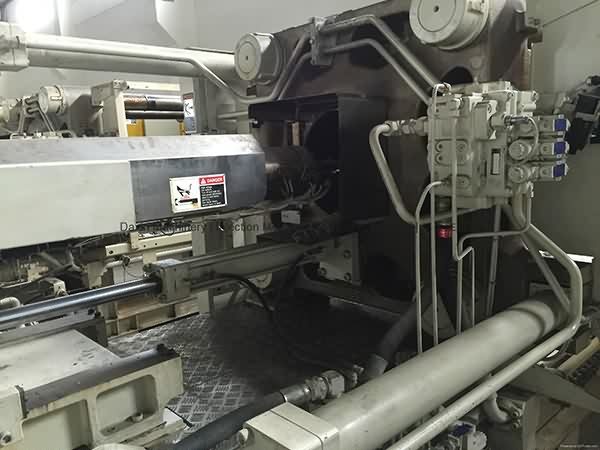

Toshiba 450t used plastic injection molding machine

Youtube: https://youtu.be/WJngGtO1BdI

Model: IS450GS.

Year: 2003.

Screw diameter: 70mm.

Injection weight: 1360g

Tie bar spacing: 810x810mm.

Controller: V10.

A few units for sale. Machines are in good working condition, kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us after Chinaplas to power on the machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

To meet the customers' over-expected gratification , we have our robust crew to offer our best over-all support which includes marketing, income, coming up with, production, excellent managing, packing, warehousing and logistics for Factory wholesale Toshiba IS450GS Used Injection Molding Machine to Mozambique Factory, The product will supply to all over the world, such as: Macedonia , Nairobi , Tunisia , Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing merchandise, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

Superfast injection molding of LSR (liquid silicon rubber) with a hybrid ENGEL e-victory 130 US and 64 cavities mold from ACH Solution.

ukázka rychlosti plně elektrického stroje JSW verze J-110AD A jak rychle běhá Váš vstřikolis ?

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.