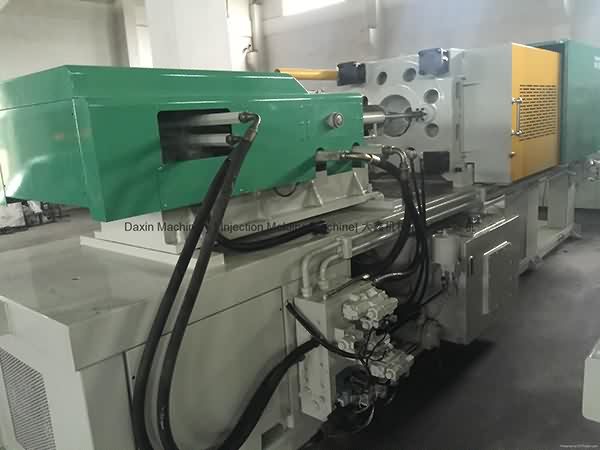

Fast delivery Chen Hsong Super Master SM250TS used Injection Molding Machine for Qatar Factory

Fast delivery Chen Hsong Super Master SM250TS used Injection Molding Machine for Qatar Factory Detail:

Taiwan Chen Hsong Super Master 250t used Injection Molding Machine for sale

Youtube Video: https://youtu.be/W0oWFc3ZjF4

Model: SM250TS.

Year: 2007..

Screw diameter: 45mm. .

Tie bar spacing: 620x620mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

How Importers And Exporters Can Benefit From The Canton Fair

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, shopper supreme" for Fast delivery Chen Hsong Super Master SM250TS used Injection Molding Machine for Qatar Factory, The product will supply to all over the world, such as: Canberra , Moscow , United Arab Emirates , Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

This tutorial explains the difference between a project and sequence in Final Cut 7.

MMC has been supplying cap slitters and TE band inverting machine systems to the closure industry for many years and has advanced the field through innovative machine design.

a) Knotched Knife Slitting Technology

Rotary Cap Slitting machines score the side wall of your plastic closure with arched slitting blade. The slitting blade has intermittent interruptions that will leave a predetermined amount of bridges to hold the Tamper Evident Band to the closure. When the closure is removed from the container for the first time, the bridges break, leaving the band on the neck of the container and demonstrating visual point of purchase tamper evidence to the consumer.

b) Cut-to-post Slitting Technology

A series of ribs are molded into the inner wall of the closure, which will eventually become the bridges that break during closure removal. The closure is rotated against a stationary blade, gradually slicing through the side wall until the blade reaches the molded-in posts.

c) Band Inverter

MMC has launched the CMBF product series to streamline the Tamper Evident Band folding and Band inverting operation. Our unit is a fully automatic multiple head continuous motion machine which is able to fold in the Tamper Evident Band retaining feature allowing the container neck to grip this feature.

For more information, please visit our website

www.mmcpackaging.com

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.