Fast delivery CLF-1000T (servo) used Injection Molding Machine to Madras Manufacturer

Fast delivery CLF-1000T (servo) used Injection Molding Machine to Madras Manufacturer Detail:

CLF-1000T (servo) used Injection Molding Machine.

Model: CLF-1000T.

Year: 2011.

Screw diameter: 105mm.

Tie bar spacing: 1060mm.

Very good working condition. Interested customer pls visit our warehouse to inspect the machine and test it running under power..

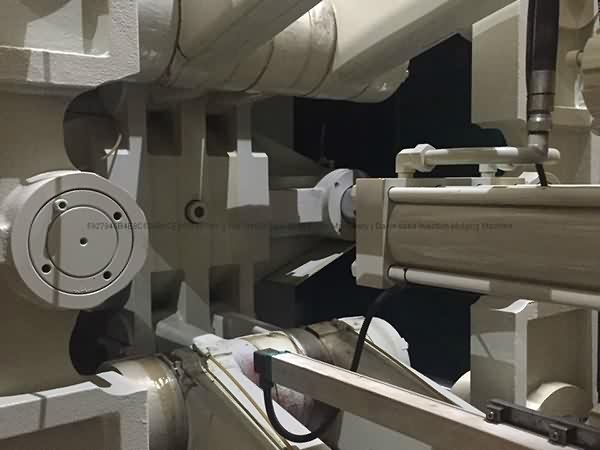

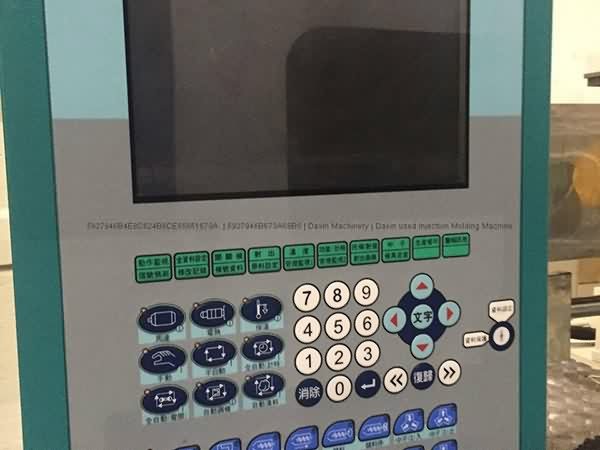

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

We normally think and practice corresponding on the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and also the living for Fast delivery CLF-1000T (servo) used Injection Molding Machine to Madras Manufacturer, The product will supply to all over the world, such as: El Salvador , Frankfurt , Sevilla , To meet the requirements of individual customers for each bit more perfect service and stable quality products. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

ENGEL victory 120 combi. Combination of technologies. IML in mold labelling + metal insert molding +combiment for injection of 2 different materials (hard and ...

Cincinnati Milacron VT110 Used Injection Molding Machine, 110 US ton, Yr. 1999, 10 oz., ZAG #7496.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!