Fixed Competitive Price Chuan Lih Fa CLF-1000T used Injection Molding Machine for Honduras Factory

Fixed Competitive Price Chuan Lih Fa CLF-1000T used Injection Molding Machine for Honduras Factory Detail:

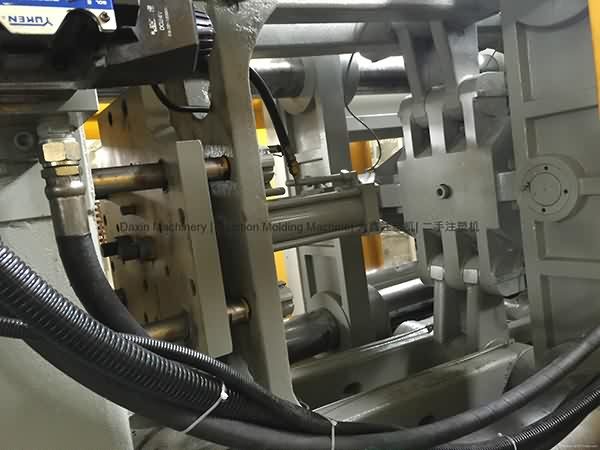

Chuan Lih Fa 1000t used Plastic Injection Molding Machine.

Youtube Video: https://youtu.be/woC2fZ-o8zA

Model: CLF-1000T.

Year: 2006.

Screw diameter: 105mm.

Tie bar spacing: 1050x990mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Plastic Injection Molding: Past, Present and Future

Our goal is to provide high quality products at competitive prices, and top-notch service to customers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Fixed Competitive Price Chuan Lih Fa CLF-1000T used Injection Molding Machine for Honduras Factory, The product will supply to all over the world, such as: US , Puerto Rico , Ireland , In order to carry out our goal of "customer first and mutual benefit" in the cooperation, we establish a professional engineering team and a sales team to supply the best service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We are your best choice.

https://www.AAdvantageLaundry.com.

Video shows the process construction of the RTM Light mold the manufacture of the piece.

Produzido por Paulo Camatta, especialista em desenvolvimentos de processos como RTM Light, infusão convencional e com pele de silicone, laminação a vácuo e fabricação de modelos e moldes. Este vídeo foi desenvolvido baseado nos cursos de capacitação operacional que ministrava no CETECOM - Centro Tecnológico de Compósitos até Fevereiro de 2017, com o objetivo de disponibilizar inovações tecnológicas em processos de compósitos poliméricos termofixos.

Este vídeo demonstra resumidamente a contrução do molde e o processo RTM Light - Resin Transfer Moulding assistido a vácuo.

Atualmente Paulo Camatta é Diretor Executivo da CRC Composites, empresa de consultoria e Representação. www.crcomposites.com.br

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.