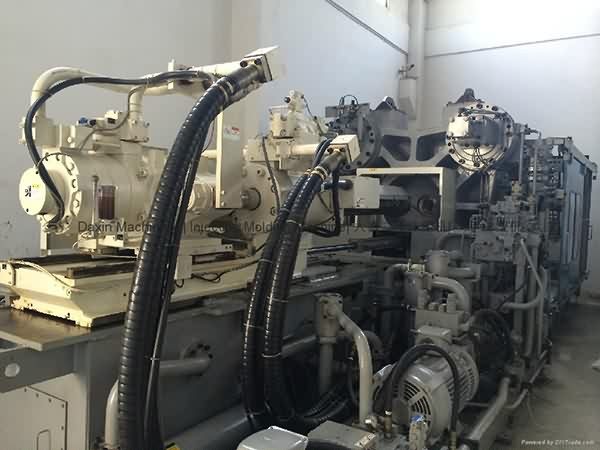

Fixed Competitive Price Mitsubishi 1300t Used Injection Molding Machine Export to United Arab emirates

Fixed Competitive Price Mitsubishi 1300t Used Injection Molding Machine Export to United Arab emirates Detail:

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Screw diameter: 100mm.

Injection volume: 4540cm^3.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Precision of Plastic Machining

We always continually offer you the most conscientious purchaser services, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Fixed Competitive Price Mitsubishi 1300t Used Injection Molding Machine Export to United Arab emirates, The product will supply to all over the world, such as: US , Montpellier , Ghana , Due to good quality and reasonable prices, our products have been exported to more than 10 countries and regions. We are looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit.

PU foaming machine for making safety shoes.

pvc braided hose extrusion machine line weifang jingda plastic machinery co.,

Weifang Jingda Plastic Machinery Co.,Ltd

Add:Changle, Weifang, Shandong, China

https://www.hoseextruder.com

Email: info@hoseextruder.com

Mobile/WhatsApp/Viber: 008615715362527

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.