Free sample for Chuan Lih Fa CLF-950TX used Injection Molding Machine for New York Manufacturers

Free sample for Chuan Lih Fa CLF-950TX used Injection Molding Machine for New York Manufacturers Detail:

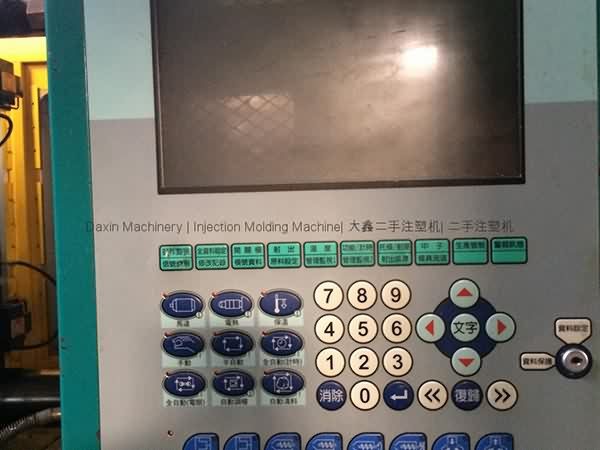

Chun Lih Fa CLF-950TX injection molding machine.

Year of manufacture: 2010.

Screw diameter: 80mm.

Tie bar spacing: 1120x1120mm.

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

The Emergence of Injection Molding in Plastic Industry

Our commission is always to provide our customers and clientele with best quality and aggressive portable digital products for Free sample for Chuan Lih Fa CLF-950TX used Injection Molding Machine for New York Manufacturers, The product will supply to all over the world, such as: Sheffield , Bahrain , Miami , Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

This tutorial explains the difference between a project and sequence in Final Cut 7.

https://www.gpmplas.com

mail:saldd@gpmplas.com

Phone:+86-13817552980

GPM MACHINERY (SHANGHAI) CO .,LTD.

Reed lee

GPM company(https://www.gpmplas.com) specializes in high quality plastic extrusion machine production , the company's technology from France .

PP PE and other recycled plastic commentary:

With the increasing consumption of plastic products, plastic waste is also increasing. At present the main waste plastic plastic film, plastic, silk and woven goods, foam, plastic crates and containers, household plastic products, plastic bags and agricultural film, etc. In addition, in recent years, one of the automotive plastics, electronics and home appliances supporting the plastic, these products after retirement became an important source of waste plastics. These plastic waste storage, transportation, processing, waiting to be processed waste plastic raw materials and post-processing application if appropriate, is bound to damage the environment and endanger the health of people.

Increased global crude oil prices, as the price of oil, one of the plastic derivative naturally have gone up, waste recycling plastics has also been referred to the primary position. Waste plastics recycling has been widely used in modern chemical industry. After the screening of waste plastic artificial classification, but also through crushing, granulation, process modification, into a variety of transparent opaque plastic particles, and then classified according to product phase, and finally become able to use recycled materials again.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.