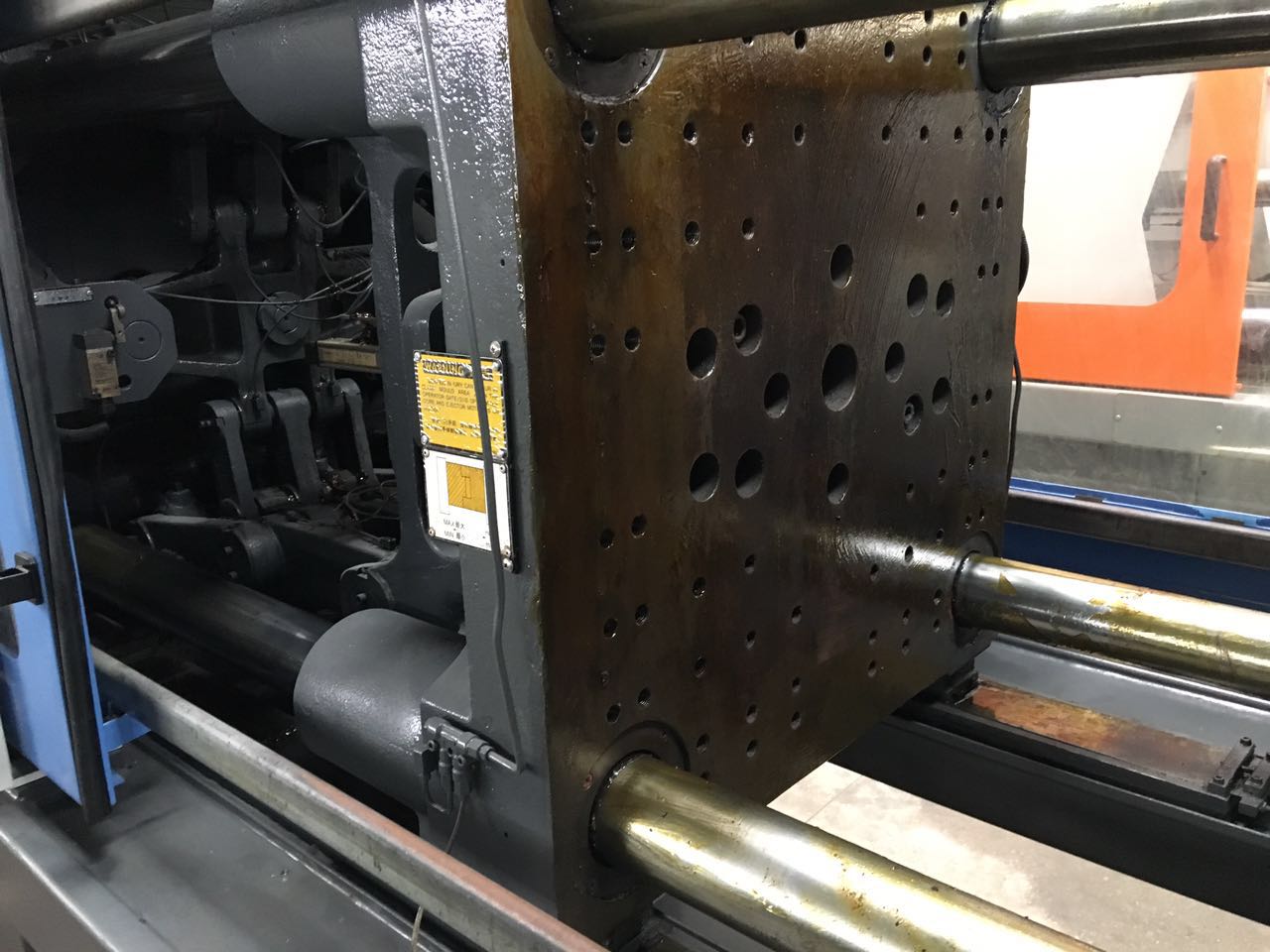

Free sample for Haitian 200t (servo) used Injection Molding Machine to India Factory

Free sample for Haitian 200t (servo) used Injection Molding Machine to India Factory Detail:

Haitian 200t (servo) used Injection Molding Machine

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

That has a sound small business credit, great after-sales service and modern production facilities, we've earned an outstanding standing amid our buyers across the earth for Free sample for Haitian 200t (servo) used Injection Molding Machine to India Factory, The product will supply to all over the world, such as: Cairo , Netherlands , South Africa , If you give us a list of merchandise you are interested in, along with makes and models, we can send you quotations. Remember to email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

Click below and get a wide information about this Used Machine: https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300034828?

PET Preform Injection Machine FROM China Evertopmachine

https://www.evertopmachine.com/

https://www.evertopmachine.com/water-filling-machine/

https://www.evertopmachine.com/carbonated-beverage-filling-machine/

https://www.evertopmachine.com/juice-tea-hot-filling-machine/

https://www.evertopmachine.com/barreled-drink-water-filling-machine/

https://www.evertopmachine.com/glass-bottle-filling-machine/

https://www.evertopmachine.com/can-filling-machine/

https://www.evertopmachine.com/oil-filling-machine/

https://www.evertopmachine.com/milk-filling-machine/

https://www.evertopmachine.com/wine-filling-machine/

https://www.evertopmachine.com/labeling-machine/

https://www.evertopmachine.com/water-treatment-system/

https://www.evertopmachine.com/blow-moulding-machine/

https://www.evertopmachine.com/injection-moulding-machine/

https://www.evertopmachine.com/automatic-bottle-packing-machine/

https://www.evertopmachine.com/other-ancillary-bottling-machine/

https://www.evertopmachine.com/other-ancillary-bottling-machine/

https://www.evertopmachine.com/other-ancillary-packing-machinery/

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.