Free sample for JSWJ450EIII used Injection Molding Machine to Jakarta Factories

Free sample for JSWJ450EIII used Injection Molding Machine to Jakarta Factories Detail:

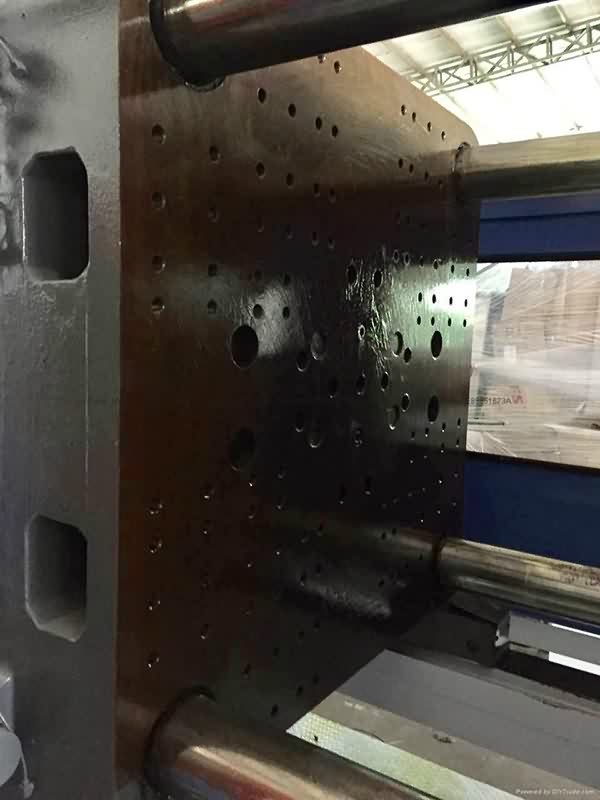

JSWJ450EIII used Injection Molding Machine.

Video:https://youtu.be/CXCqYjH1cto

Model: JSWJ450EIII.

Year: 2006.

Screw diameter: 84mm.

Tie bar spacing: 810x810mm.

Machine is in very good working condition. Interested customer is welcome to visit our warehouse to inspect the machine and test it running under power.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm to the long-term to develop together with consumers for mutual reciprocity and mutual advantage for Free sample for JSWJ450EIII used Injection Molding Machine to Jakarta Factories, The product will supply to all over the world, such as: Peru , India , venezuela , The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

Pressa verticale JSW all-electric.

Water Damage Restoration? Lindenhurst, NY Call (631) 888-6080 24/7, Call Now (613) 888-6080, or go to our website for more details. Open 24 Hours

https://westbabylonrestorationpros.com/

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.