Free sample for Toshiba IS650GT Used Injection Molding Machine for Iraq Manufacturers

Free sample for Toshiba IS650GT Used Injection Molding Machine for Iraq Manufacturers Detail:

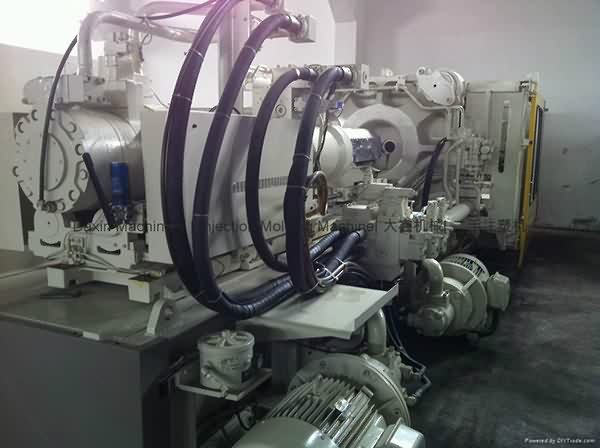

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT-59A.

Screw diameter: 90/95mm.

Tie bar spacing: 980x980mm.

Year: 2004/2006.

Controller type: V10.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Emergence of Injection Molding in Plastic Industry

To create much more benefit for consumers is our company philosophy; customer growing is our working chase for Free sample for Toshiba IS650GT Used Injection Molding Machine for Iraq Manufacturers, The product will supply to all over the world, such as: Iran , Florence , Islamabad , Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

two color silicone mat / pad, perfectly realized with Midgold LSR silicone rubber. Any interests with our LSR silicone rubber material, let us know here, or contact ...

H. Galow Company, Inc. is an ISO 9001:2000 Certified, veteran manufacturer of high precision, tight tolerance parts for the medical, aerospace, optics, electronics and commercial industries. Located in Norwood, New Jersey. Please contact us at (201) 768-0547.

We take pride in providing a full service machine shop. We have the capability to complete virtually all machining in-house thereby reducing production lead-time and cost. Our state-of-the-art equipment includes:

- 7-axis Swiss type screw machines

- 5-axis wire EDM, RAM EDM and EDM hole popping machines

- Gear cutting and grinding

- 4 & 5-axis CNC milling machines

- CNC turning machines (lathe)

Our experienced tool room engineers build fixtures and specialized tooling in-house to support prototype and/or high volume production requirements. We are experienced in machining a wide variety of engineered plastics and metals.

We also provide testing and assemblies:

- Sub-assembly

- Final product assembly

- Collating

- Kitting and final packaging

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.