Good Quality Chuan Lih Fa CLF-1000T used Injection Molding Machine to Ukraine Factory

Good Quality Chuan Lih Fa CLF-1000T used Injection Molding Machine to Ukraine Factory Detail:

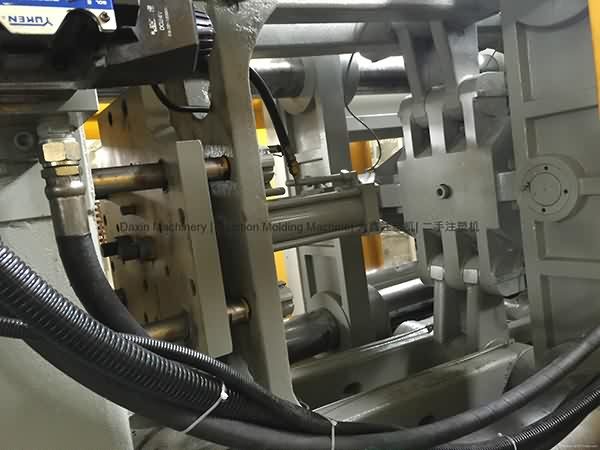

Chuan Lih Fa 1000t used Plastic Injection Molding Machine.

Youtube Video: https://youtu.be/woC2fZ-o8zA

Model: CLF-1000T.

Year: 2006.

Screw diameter: 105mm.

Tie bar spacing: 1050x990mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Precision of Plastic Machining

Fast and superior quotations, informed advisers to help you choose the correct merchandise that suits all your requirements, a short generation time, responsible quality control and different services for paying and shipping affairs for Good Quality Chuan Lih Fa CLF-1000T used Injection Molding Machine to Ukraine Factory, The product will supply to all over the world, such as: The Swiss , Bhutan , Pakistan , Welcome to visit our company, factory and our showroom where displays various hair products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

Pressa verticale JSW all-electric.

This video was uploaded from an Android phone.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!