Good Quality Chuan Lih Fa CLF-1000T used Injection Molding Machine Wholesale to UK

Good Quality Chuan Lih Fa CLF-1000T used Injection Molding Machine Wholesale to UK Detail:

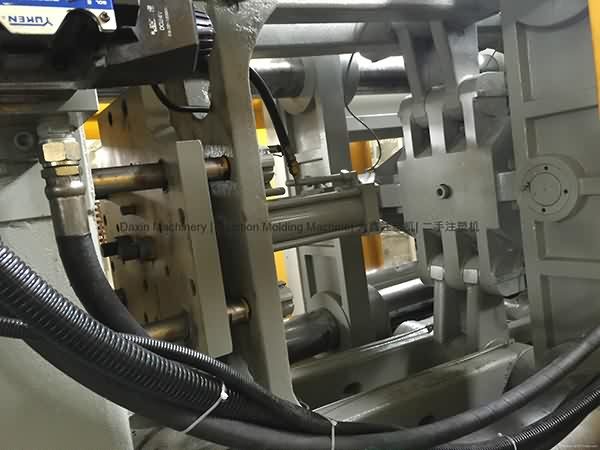

Chuan Lih Fa 1000t used Plastic Injection Molding Machine.

Youtube Video: https://youtu.be/woC2fZ-o8zA

Model: CLF-1000T.

Year: 2006.

Screw diameter: 105mm.

Tie bar spacing: 1050x990mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Emergence of Injection Molding in Plastic Industry

Our staff are usually in the spirit of "continuous improvement and excellence", and while using the top-quality high-quality items, favorable value and superior after-sales services, we try to acquire each and every customer's belief for Good Quality Chuan Lih Fa CLF-1000T used Injection Molding Machine Wholesale to UK, The product will supply to all over the world, such as: Mumbai , Bahamas , Jersey , Our items have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll supply the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

Jet Engine Automation Co., Ltd. www.jetrobot.com.tw.

This video was uploaded from an Android phone.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.