Good quality JSW 50t All-Electric used Injection Modling Machine for Chile Manufacturers

Good quality JSW 50t All-Electric used Injection Modling Machine for Chile Manufacturers Detail:

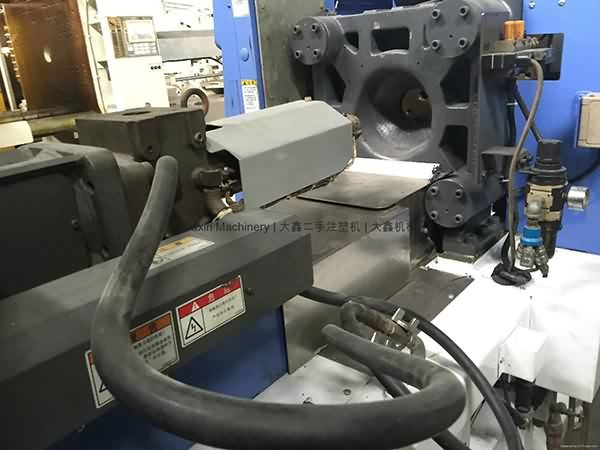

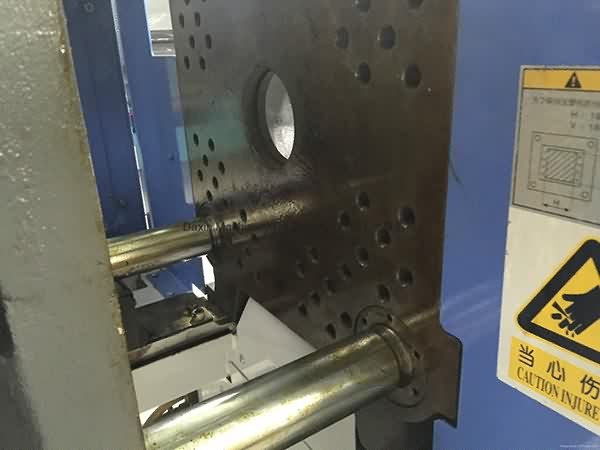

JSW 50t All-Electric Used Injection Molding Machine

Model: JSWJ50ELIII.

Year: 2015.

Screw diameter: 20mm.

Tie bar spacing: 310x31010mm.

Machine is driven by electricity. It is in very good running condition. Interested customer can visit our warehouse to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

Fast and great quotations, informed advisers to help you choose the correct solution that suits all your requirements, a short creation time, responsible top quality manage and distinct providers for paying and shipping affairs for Good quality JSW 50t All-Electric used Injection Modling Machine for Chile Manufacturers, The product will supply to all over the world, such as: Puerto Rico , United States , Iraq , Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

This is a TiTech Optical Sorter. Basically, the machine uses a conveyor belt to drive shredded plastic pieces under an optical sensor which then uses an air-jet to pick or "shoot" out the desired plastic type. The optical sorter is able to process and separate a wide variety of plastic scraps including ABS, ABS/PC, HIPS, PS, PET, PETG, PVC, PP, etc...

Small investment idea / plan / programme of produce any mobile phone case / skin. https://www.chinee.net Start own small business of making mobile phone case / skin for any brand mobile phone such as Samsung, iPhone, LG, HTC, Huawei, Coolpad, Lenovo, Lumia, Xiaomi, Smartisan, ZTE, Blackberry...etc. DAQIN smart mobile tempered glass screen protector cutting machine.

Start your own small business with this machine easily.

DAQIN, Poineer and leader of custom mobile case business, sell well in 135 countries since 2002.

Web: https://www.chinee.net

Email: daqin@chinee.net

Tel: 0086 10 51606566

Facebook: https://www.facebook.com/cellphoneskin

Twitter: https://twitter.com/diyskin

Instagram: idskin

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!