Good Wholesale Vendors Haitian 160t (servo) used Injection Molding Machine for Austria Manufacturers

Good Wholesale Vendors Haitian 160t (servo) used Injection Molding Machine for Austria Manufacturers Detail:

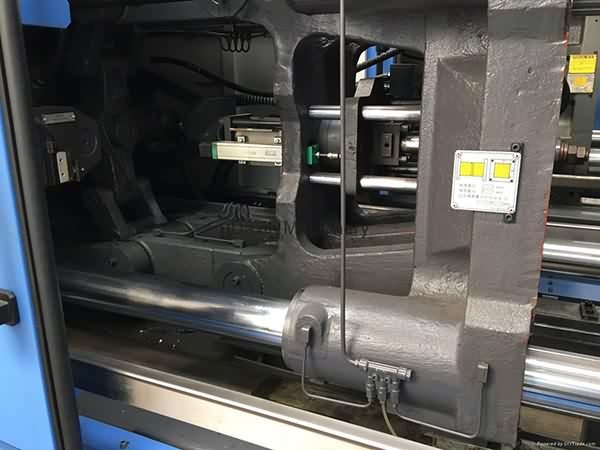

Haitian 160t (servo) used Injection Molding Machine

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, shopper supreme" for Good Wholesale Vendors Haitian 160t (servo) used Injection Molding Machine for Austria Manufacturers, The product will supply to all over the world, such as: Salt Lake City , Ukraine , Malta , We offer OEM services and replacement parts to meet the varying needs of our customers. We offer competitive price for quality products and we will make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

More information & Pictures: https://www.evermak.com/ITEM.PRO?S=5594&_setlang=EN

Used Rajoo PP Film Machine. Plastic Film Extruder For Sale In Karnataka

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.