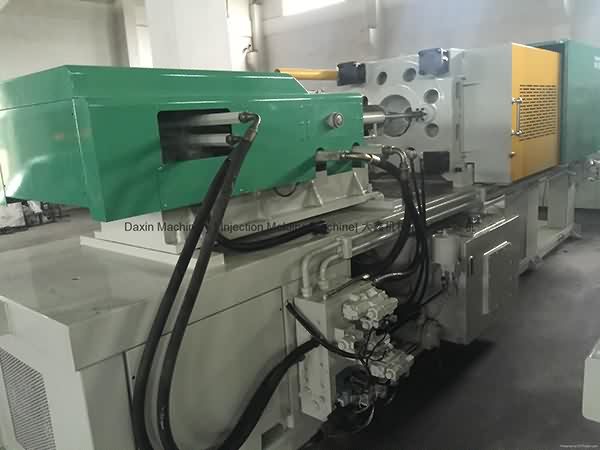

High Performance Chen Hsong Super Master SM250TS used Injection Molding Machine to Rotterdam Manufacturers

High Performance Chen Hsong Super Master SM250TS used Injection Molding Machine to Rotterdam Manufacturers Detail:

Taiwan Chen Hsong Super Master 250t used Injection Molding Machine for sale

Youtube Video: https://youtu.be/W0oWFc3ZjF4

Model: SM250TS.

Year: 2007..

Screw diameter: 45mm. .

Tie bar spacing: 620x620mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Plastic Injection Molding: Past, Present and Future

Our mission will be to grow to be an innovative supplier of high-tech digital and communication devices by giving worth added design and style, world-class production, and service capabilities for High Performance Chen Hsong Super Master SM250TS used Injection Molding Machine to Rotterdam Manufacturers, The product will supply to all over the world, such as: Costa Rica , Chicago , Surabaya , Look forward to the future, we will focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our comprehensive advantages and strive for building.

WE PROVIDE ALL KINDS OF PRODUCTS FOR SHOES PRODUCTION - MACHINE / MOULDS / MATERIALS / TURN KEY PRODUCTS . please contact ...

https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300032075?OpenDocument&ln=en&origin=YouTube Email: ...

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!