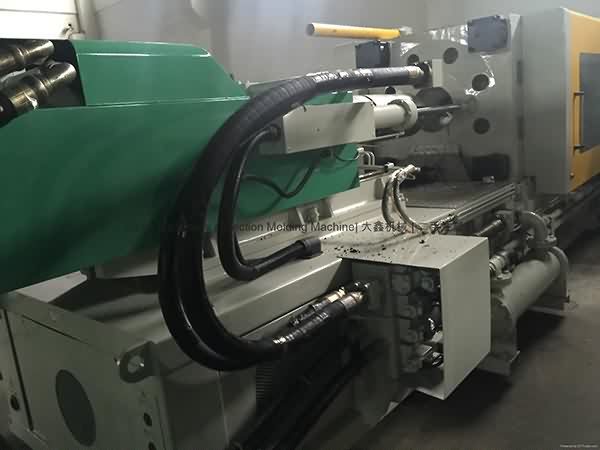

High Performance Chen Hsong Super Master SM450TS used Injection Molding Machine to Bangladesh Factories

High Performance Chen Hsong Super Master SM450TS used Injection Molding Machine to Bangladesh Factories Detail:

Taiwan Chen Hsong Super Master 450t used Injection Molding Machine

Video: https://youtu.be/lo5SPPvPMCo

Model: SM450TS.

Year 2009.

Screw diameter: 60mm.

Tie bar spacing: 820x820mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

Making Plastic – Plastic Injection Moulding

We emphasize advancement and introduce new products into the market each year for High Performance Chen Hsong Super Master SM450TS used Injection Molding Machine to Bangladesh Factories, The product will supply to all over the world, such as: Morocco , El Salvador , Islamabad , We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

Video of Nissei machine working.

Mechanical Systems's Fully Automatic Pet Bottle Blowing Machine ,equipment is one high precision and speedy to make, bottles used for Water, Carbonated drinks, Hot fill juices, Pharmaceuticals & cosmetics , but also can used for different bottle shapes filling in one machine. With change over parts. Greatly improve the equipment usage

scope. Production capacity is from 2,000 bottles per hour to 4,000 bottles per hour can be chosen by customers. Main-frame machine adopts frequency conversion timing motor, convenient adjustment speed within throughput.

We are making 2 cavity, 4 cavity, 6 cavity Blow Machines fully auto as well as semi auto 2 cavity with auto drop feature as well.

C. Machine Features:

C.1. Stably performance with advanced PLC.

C.2. Conveying preforms automatically with conveyor.

C.3. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared preheated.

C.4. High adjustability to enable the preheated to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheated with an automatic thermostatic apparatus.

C.5. High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

C.6. No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

C.7. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

C.8. Strong clamping force with high pressure and double crank links to lock the mold.

C.9. Two ways of operating: automatic and manual.

C.10. Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

C.11. Low cost, high efficiency, easy operation, easy maintenance, etc, with automatic technological process.

C.12. Contamination is avoided for the bottle body.

C.13. Ideal effect of the chilling with the chilling system.

C.14. Easy installation and starting

C.15. Low rejection rate: less than 0.2 percent.

We, Steplead International Co. Ltd, are one of the leading companies in designing and manufacturing water filling machine, hot filling machine, carbonated beverage filling machine, and other liquid filling machine in mainland China. We also manufacture PET bottle blowing machine, water filter, labeling machine, injection molding machine, water dispensers (water coolers), ice maker and fireworks sparklers making machines.

Steplead, ISO 9001:2000-certified enterprise, covers total area of 10, 000 square meters, equipped with 5 production lines. We provide one-stop technical service, including water plant layout design, installation, debugging, commissioning and maintenance. We can provide the technical training for clients. When the equipment gets something wrong, our technicians will provide solutions within several hours. Besides, if necessary, we can dispatch the technician to solve the problems on spot.

For more information about our products, please feel free to contact us by

John Lau.

Sales Manager

Steplead International Co.,Ltd.

Address: Shenhua Industry Zone, Shang Mei Lin, Futian District, Shenzhen, China .

Cel: (+86) 13670181318

Email: johnlauvip@gmail.com

Website: www.steplead.com

Facebook: https://www.facebook.com/lau.john.942

Twitter: https://twitter.com/Steplead_filler

Google+:https://plus.google.com/+StepleadFillTech

Blogger:https://stepleadcom.blogspot.hk/

********************************************************

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!