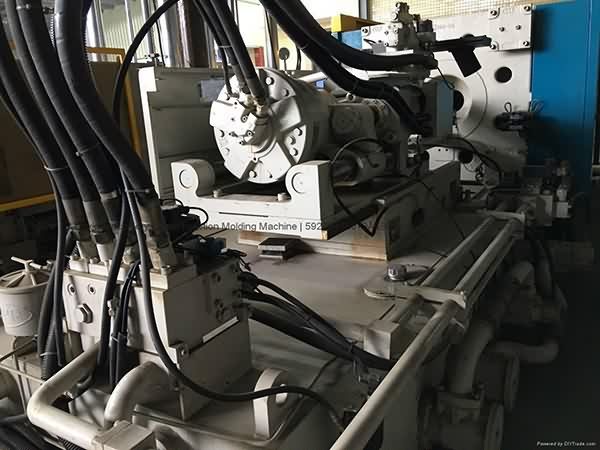

High Performance Chuan Lih Fa CLF-650TX used Injection Molding Machine Export to Armenia

High Performance Chuan Lih Fa CLF-650TX used Injection Molding Machine Export to Armenia Detail:

Chuan Lih Fa CLF-650TX Used Injection Molding Machine.

Model: CLF-650TX.

Year: 2008.

Screw diameter: 85mm.

Tie bar spacing: 910x910mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

We always get the job done being a tangible workforce making sure that we can easily give you the very best quality as well as finest selling price for High Performance Chuan Lih Fa CLF-650TX used Injection Molding Machine Export to Armenia, The product will supply to all over the world, such as: Leicester , Guatemala , Botswana , Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a "people-oriented, meticulous manufacturing, brainstorm, construct brilliant" organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we are going to be pleased to serve you.

We have experience supplying closing machines for a variety of closures with various hinge styles and latching features. Our closing machines use repeatable and highly efficient techniques to perform intricate closing functions for the following types of closures:

- Flip-Top closures for condiments

- Dispensing closures for the Hair Care market

- Rectangular Coffee closures

- Single-door and twin-door closures for spices and grated cheese & non-dairy creamer

- Beverage closures

- Custom designed hinged closures

For more info: info@mmcpackaging.com

www.mmcpackaging.com

Used 1000 Ton Engel Injection Molding Machine, 160oz, Model ES 7050/1000AH/CC100, 1999 Vintage Tonnage...........................1000 ton Shot ...

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.