High Performance CLF-200TY used Injection Molding Machines Wholesale to Birmingham

High Performance CLF-200TY used Injection Molding Machines Wholesale to Birmingham Detail:

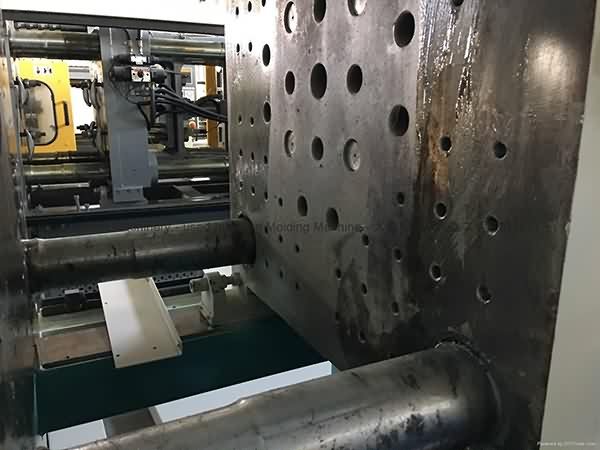

CLF-200TY used Injection Molding Machine.

Model; CLF-200TY.

Year: 2012.

Tie bar spacing: 560x560mm.

Two units available. Very good working condition. Interested customer can visit our warehouse to inspect the machines and test them running under power..

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Plastic Injection Molding: Past, Present and Future

The corporate keeps towards the operation concept "scientific administration, superior quality and performance primacy, client supreme for High Performance CLF-200TY used Injection Molding Machines Wholesale to Birmingham, The product will supply to all over the world, such as: Hanover , Georgia , Porto , In order to carry out our goal of "customer first and mutual benefit" in the cooperation, we establish a specialist engineering team and a sales team to supply the best service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We have been your best choice.

Manufacturer,Distributor,Exporters & Supplier Of World Class Machinery (040-64646688)

This is a video of the Egg Carton manufacturing equipment at work. It uses scrap paper as raw material.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!