High Performance CLF-400T used Injection Molding Machine to Brazil Manufacturers

High Performance CLF-400T used Injection Molding Machine to Brazil Manufacturers Detail:

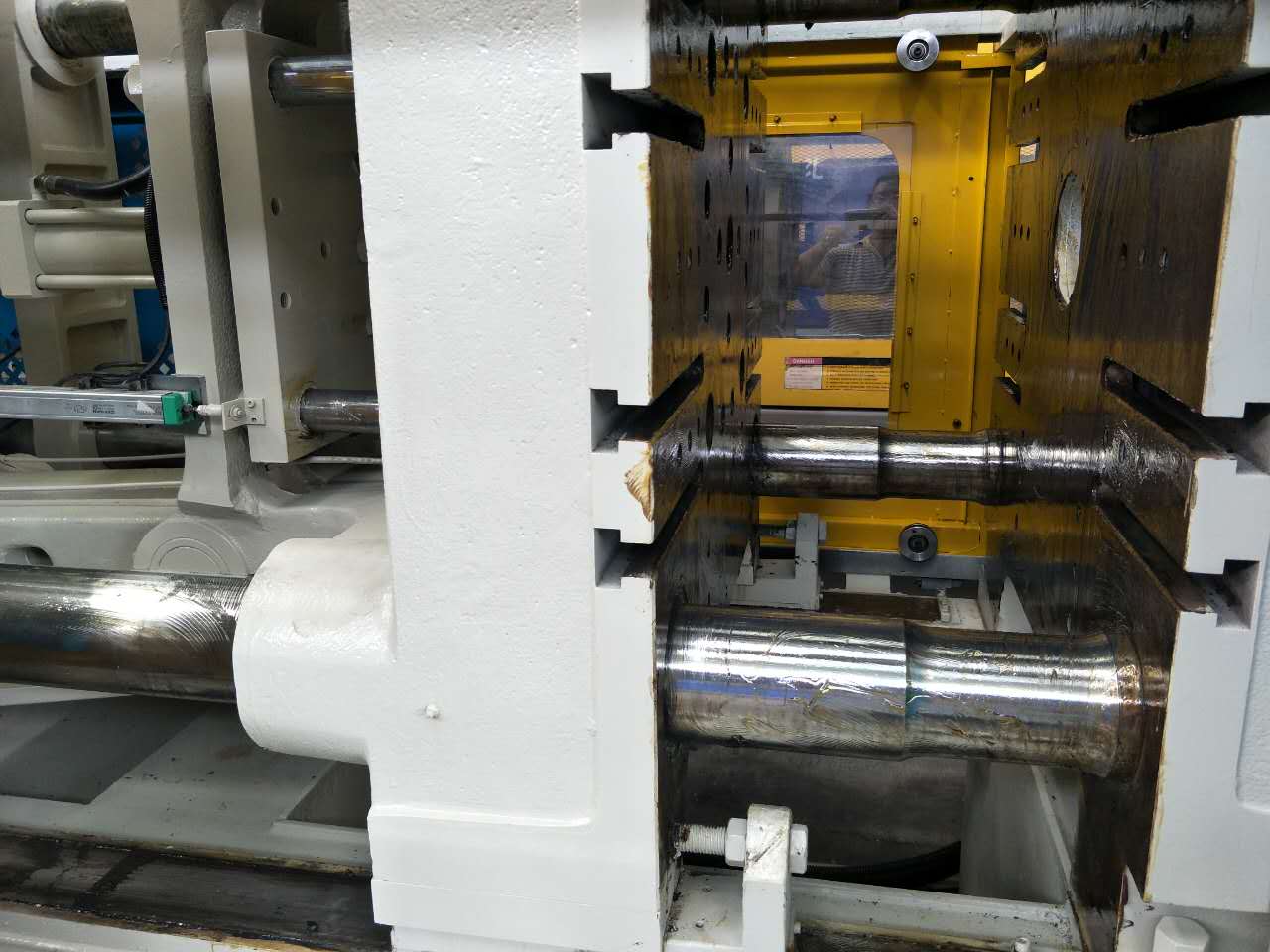

CLF-400T used Injection Molding Machine

Model: CLF-400T.

Year: 2012.

Screw diameter: 60mm.

Tie bar spacing: 680mm.

Good working condition. Interested customer can visit our warehouse to inspect machine and test it running under power..

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Plastic Injection Molding: Past, Present and Future

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our enterprise to the long-term to produce together with clients for mutual reciprocity and mutual profit for High Performance CLF-400T used Injection Molding Machine to Brazil Manufacturers, The product will supply to all over the world, such as: Vietnam , Hyderabad , Madagascar , We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

This video is pulp molding machine to produce egg tray, just change the mold in the forming system, this kind of machine also can produce egg carton, egg box, egg tray, fruit tray, bottle tray, paper shoe stretcher, agricultural seedling tray, industrial production packing, paper medical disposable trays etc..

Our website is www.eggtraymachine-sh.com / More information about the machine please send email to: vanilla@eggtraymachine-sh.com vanillashuanghuan@gmail.com / Phone Number: 0086-15673277080 / Skype: vanilla.ling

Milacron VL600-76, 600ton, 95 ounce, CAMAC VEL controls, new 1994. for sale by owner 586.228.2100.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!