High Performance Niigata 180t used All-electric Injection Molding Machine to San Francisco Manufacturer

High Performance Niigata 180t used All-electric Injection Molding Machine to San Francisco Manufacturer Detail:

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

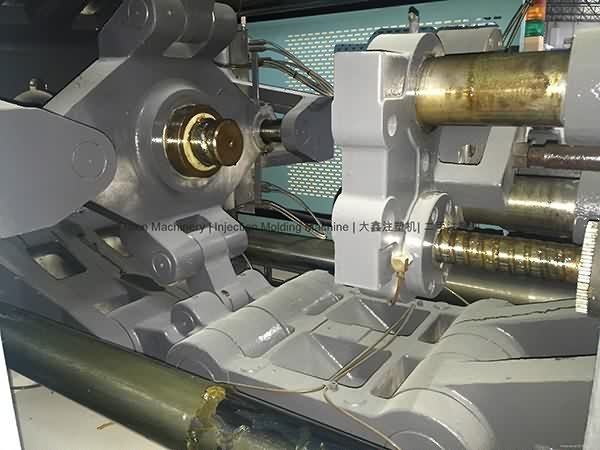

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Plastic Injection Molding: Past, Present and Future

Bear "Customer first, High quality first" in mind, we perform closely with our consumers and provide them with efficient and experienced services for High Performance Niigata 180t used All-electric Injection Molding Machine to San Francisco Manufacturer, The product will supply to all over the world, such as: Cambodia , Zimbabwe , Finland , If you are for any reason unsure which product to select, do not hesitate to contact us and we are going to be delighted to advise and assist you. This way we are going to be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We have been looking for more and more customers to create the glorious future.

PMMA lamp cover blow moulding machine

Semi-automatic machine , from PMMA preform to lamp cover .

For more details, please contact susan821123@gmail.com Skype: susan821123.

樺欽HC-280四缸/柱內560/1997年/曲手+模板104年有全新整修/盟立電腦/目前做PC塑料.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.