High Quality Automatic Pet Bottle Injection Molding Machine

Reliable good quality and very good credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality 1st, purchaser supreme" for High Quality Automatic Pet Bottle Injection Molding Machine, We've been now searching ahead to even increased cooperation with abroad consumers determined by mutual positive aspects. In case you are intrigued in almost any of our solutions, remember to experience totally free to speak to us for additional facts.

Reliable good quality and very good credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality 1st, purchaser supreme" for Injection Molding Machine, Plastic Injection Machine, Syringe Injection Molding Machine, Based on goods with high quality, competitive price, and our full range service, we've accumulated experienced strength and experience, and now we have built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality products and solutions and passionate service. Let's open a new chapter of mutual benefit and double win.

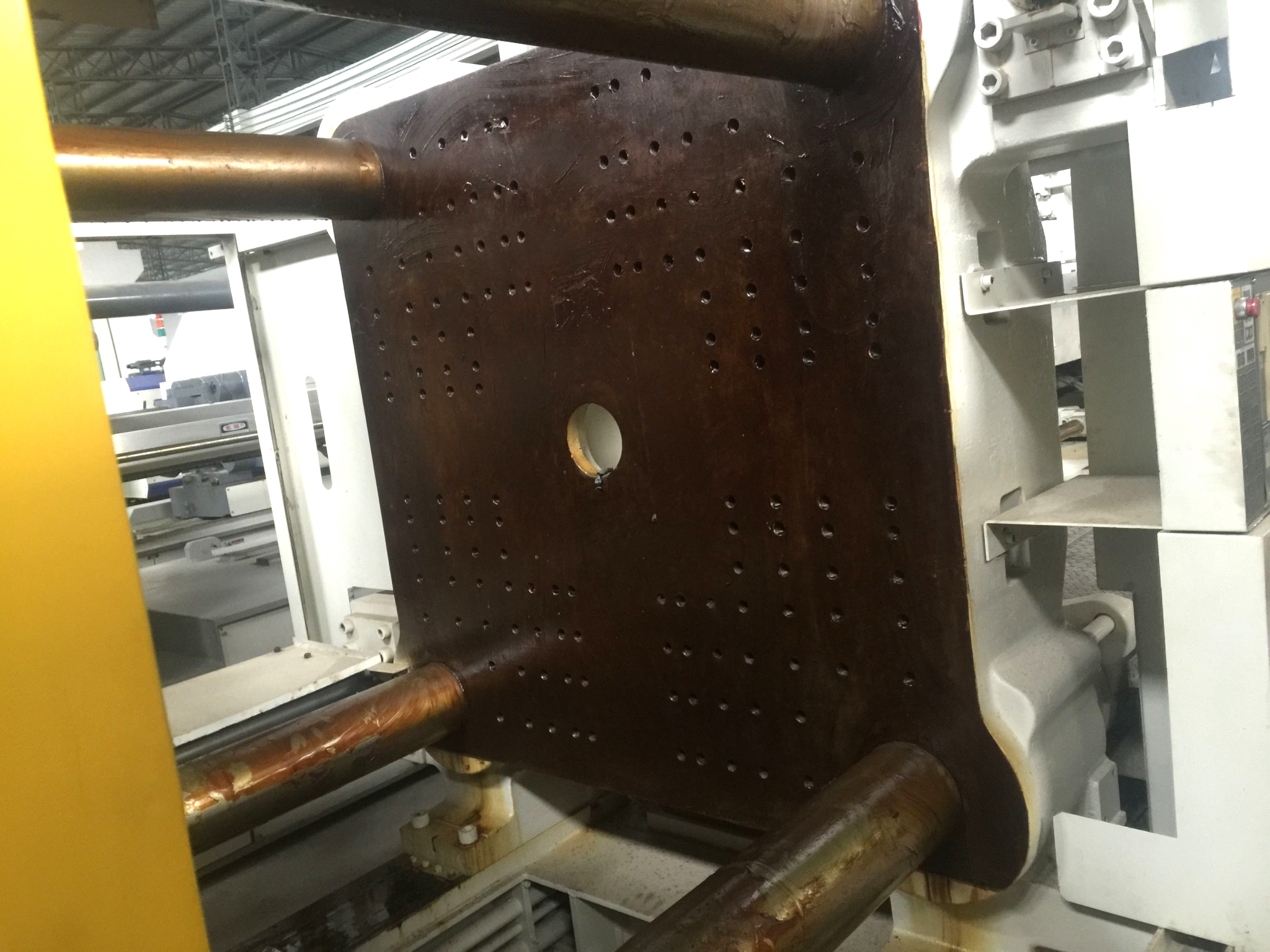

Toshiba IS850GT used injection molding machine.

Model: IS850GT

Year: 2003/2005.

Screw diameter: 105mm.

Tie bar spacing: 1080mm.

Controller type: v10.

Youtube: https://youtu.be/6uC96HMV8CY

Machine is in good condition. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou.Interested buyer is welcome to visit our warehouse during Chinaplas to power on machine for test-run.

Why choose Daxin?

- Wide range of machines: Over 200 machines (20-2000t) in 10000 sqm warehouse (Largest collection of Japanese machines in China)

- Rich experience in export: one-stop solution including dismantling of machines, loading, moving, custom clearing (many agents cannot clear custom for used machines), shipment, assembling and commissioning of machines.

- All machines can be powered on for test-run. All machines can be viewed under one roof in our warehouse.

- Post-sale support: providing spare parts, commissioning machine, inputting program, repairing PCB boards or other machine parts

- Quality assured: All machines parts are checked thoroughly, including pumps, toggle, screw, barrel, oil seals, ball bearing, platen.etc.

- Any defective parts are repaired or replaced if beyond repair.

- Have exported to more than 30 countries : South East Asia, South Asia, Australia , Middle East, Africa, South America, Central America.

Product Image

https://www.arburg.com - A two-component injection moulding machine ALLROUNDER 902 S with an innovative 32-cavity cube mould produces in just 10 ...

This video is taken in Chinaplas2016 Shanghai. Machine in the video is our latest model: HFTF-80T which is designed special for high yield production need with forming area of 762*470mm. Sample cup in the video is pet material with 92.5mm diameter.

APPLICATION:

HFTF-80T-H Automatic Thermoforming Machine suitable for PP, HIPS, PVC , PET,ETC. sheet.

Main Technical Specification

1- Max. Forming Area 762×470mm

2- Max. Forming Depth 180mm

3-Clamping Force 650KN

4- Max Sheet Width Range 820mm

5- Sheet Thickness 0.4-2.5mm

6- Air Pressure 0.7-0.85mpa

7- Water Consumption 50L/min

8- Air Consumption 5000L/min

9- Max.No-load Speed 42 Cycles/min

10- Power (Three Phase Four Wire) 3×380V+N+PE.50HZ

11- Heating Power 150kw

12- Main Motor Power 15kw

13- Stretch Motor Power 15kw

14- Feeding Motor Power 5.5kw

15- Machine Weight 15500kg

16- Dimension 13000×4500×3800mm