High Quality for Chuan Lih Fa CLF-650TX used Injection Molding Machine to Cyprus Factories

High Quality for Chuan Lih Fa CLF-650TX used Injection Molding Machine to Cyprus Factories Detail:

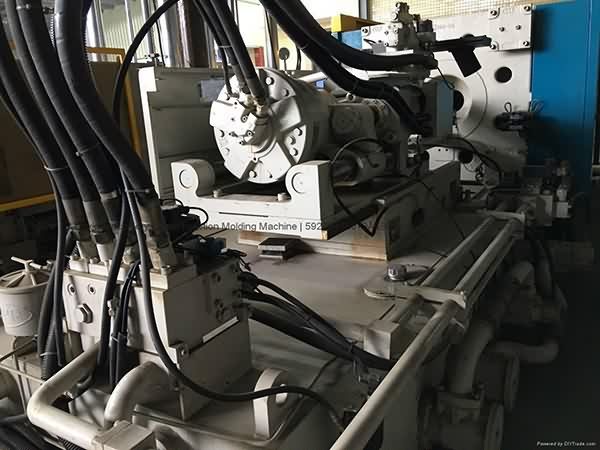

Chuan Lih Fa CLF-650TX Used Injection Molding Machine.

Model: CLF-650TX.

Year: 2008.

Screw diameter: 85mm.

Tie bar spacing: 910x910mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Plastic Injection Molding: Past, Present and Future

By using a full scientific excellent administration method, great quality and fantastic religion, we get good reputation and occupied this discipline for High Quality for Chuan Lih Fa CLF-650TX used Injection Molding Machine to Cyprus Factories, The product will supply to all over the world, such as: Leicester , Colombia , Uruguay , Our company's main items are widely used all over the world; 80% of our products and solutions exported to the United States, Japan, Europe and other markets. All stuff sincerely welcome guests come to visit our factory.

two color silicone mat / pad, perfectly realized with Midgold LSR silicone rubber. Any interests with our LSR silicone rubber material, let us know here, or contact ...

pvc braided hose extrusion machine line weifang jingda plastic machinery co.,

Weifang Jingda Plastic Machinery Co.,Ltd

Add:Changle, Weifang, Shandong, China

https://www.hoseextruder.com

Email: info@hoseextruder.com

Mobile/WhatsApp/Viber: 008615715362527

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!