High Quality for CLF-200TY used Injection Molding Machines Wholesale to Morocco

High Quality for CLF-200TY used Injection Molding Machines Wholesale to Morocco Detail:

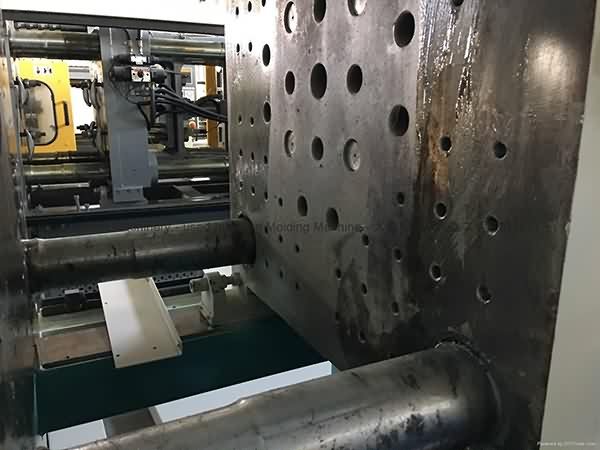

CLF-200TY used Injection Molding Machine.

Model; CLF-200TY.

Year: 2012.

Tie bar spacing: 560x560mm.

Two units available. Very good working condition. Interested customer can visit our warehouse to inspect the machines and test them running under power..

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Plastic Injection Molding: Past, Present and Future

Persisting in "High good quality, Prompt Delivery, Aggressive Price", we've established long-term cooperation with shoppers from each overseas and domestically and get new and previous clients' high comments for High Quality for CLF-200TY used Injection Molding Machines Wholesale to Morocco, The product will supply to all over the world, such as: Atlanta , belarus , Peru , As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

Medium system for PETRI plates production with ENGEL victory 300 injection molding machine, two ENGEL linear robot and two 8 cavities molds

We are the manufacturer who was founded in 1976 and has been manufacturing and selling dies and plastic parts. We develop our business mainly in Japan. Our motto is to focus on improvement of the quality of dies for plastics and plastic parts and to make products without compromise. We, who have thoroughly mastered the knowledge of dies, deliver low-priced yet high-quality products for dies and parts necessary for mass production of automobiles, motorcycles, outboard engines, home electronics, and housing components. In addition, for quality control, we have various inspection facilities including three-dimensional measuring instruments and established the checking system to prevent defective moldings. We respond to customers' needs by the one-stop production system that performs trial production, die making, resin part manufacturing and delivery as well as by our highly value-added products. If you wish to have a quick delivery, cost reduction and high quality, please contact us.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.