High Quality for JSWJ450EIII used Injection Molding Machine to Turin Manufacturer

High Quality for JSWJ450EIII used Injection Molding Machine to Turin Manufacturer Detail:

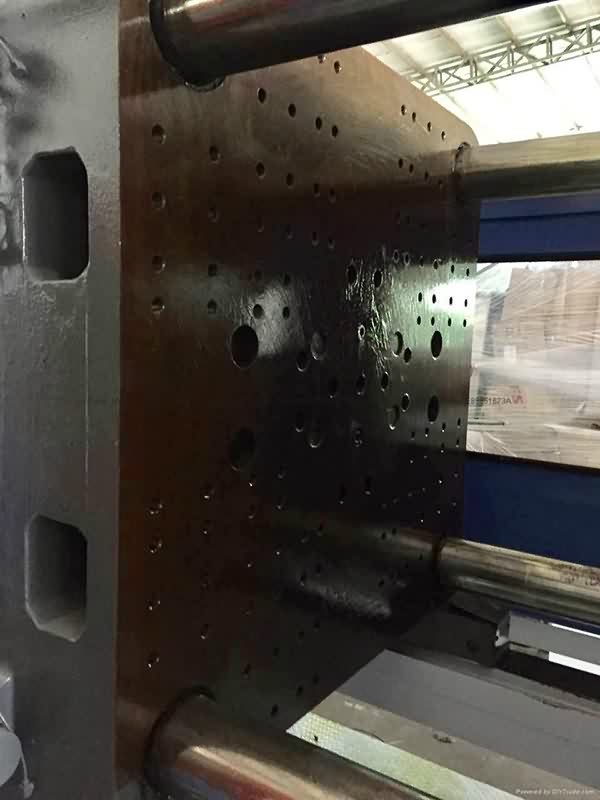

JSWJ450EIII used Injection Molding Machine.

Video:https://youtu.be/CXCqYjH1cto

Model: JSWJ450EIII.

Year: 2006.

Screw diameter: 84mm.

Tie bar spacing: 810x810mm.

Machine is in very good working condition. Interested customer is welcome to visit our warehouse to inspect the machine and test it running under power.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Plastic Injection Molding: Past, Present and Future

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for High Quality for JSWJ450EIII used Injection Molding Machine to Turin Manufacturer, The product will supply to all over the world, such as: Swaziland , Brisbane , Mauritania , We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable merchandise quality , increase customers' satisfaction and achieve win-win situation .

This video is taken in Chinaplas2016 Shanghai. Machine in the video is our latest model: HFTF-80T which is designed special for high yield production need with forming area of 762*470mm. Sample cup in the video is pet material with 92.5mm diameter.

APPLICATION:

HFTF-80T-H Automatic Thermoforming Machine suitable for PP, HIPS, PVC , PET,ETC. sheet.

Main Technical Specification

1- Max. Forming Area 762×470mm

2- Max. Forming Depth 180mm

3-Clamping Force 650KN

4- Max Sheet Width Range 820mm

5- Sheet Thickness 0.4-2.5mm

6- Air Pressure 0.7-0.85mpa

7- Water Consumption 50L/min

8- Air Consumption 5000L/min

9- Max.No-load Speed 42 Cycles/min

10- Power (Three Phase Four Wire) 3×380V+N+PE.50HZ

11- Heating Power 150kw

12- Main Motor Power 15kw

13- Stretch Motor Power 15kw

14- Feeding Motor Power 5.5kw

15- Machine Weight 15500kg

16- Dimension 13000×4500×3800mm

ENGEL shows a fully automated production system of of PETRI plates. Mold has 4 cavities. Lids and bases are assembled and than packed in a plastic envelope.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!