Hot New Products Mitsubishi 160t used Injection Molding Machine Supply to Zimbabwe

Hot New Products Mitsubishi 160t used Injection Molding Machine Supply to Zimbabwe Detail:

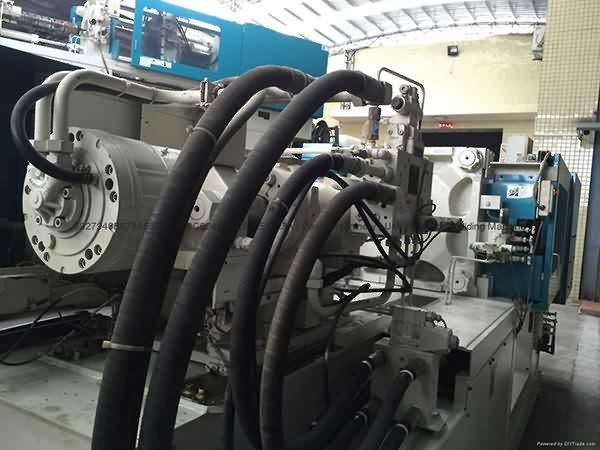

Mitsubishi 160t used Injection Molding Machines for sale.

Model: 160MSV.

Year: 2005.

Screw diameter: 45mm.

Tie bar spacing: 560m.

Very good running condition.

Interested customers can visit our warehouse to inspect the machine.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

How Importers And Exporters Can Benefit From The Canton Fair

We are convinced that with joint endeavours, the small business between us will bring us mutual benefits. We could assure you products quality and competitive selling price for Hot New Products Mitsubishi 160t used Injection Molding Machine Supply to Zimbabwe, The product will supply to all over the world, such as: Pretoria , Buenos Aires , Saudi Arabia , The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products have been exported to more than 15 countries in the world and have been widely used by customers.

Afri Medical are a leading Egyptian manufacturer of medical consumables founded in 1984; Owns and operates a facility covering 9000 m2 in 10th of Ramadan ...

Manufacturer: Toshiba Model No.: 840M71/ISF90PVL Inventory No.: 0616-226-0107 Aisle: 12A Weight (lbs.): 8215 Price (current as of 7/12/16): $4999 15'' x 23'' ...

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.