Hot New Products Sumitomo 130t All-Electric used Injection Molding Machine to Honduras Manufacturer

Hot New Products Sumitomo 130t All-Electric used Injection Molding Machine to Honduras Manufacturer Detail:

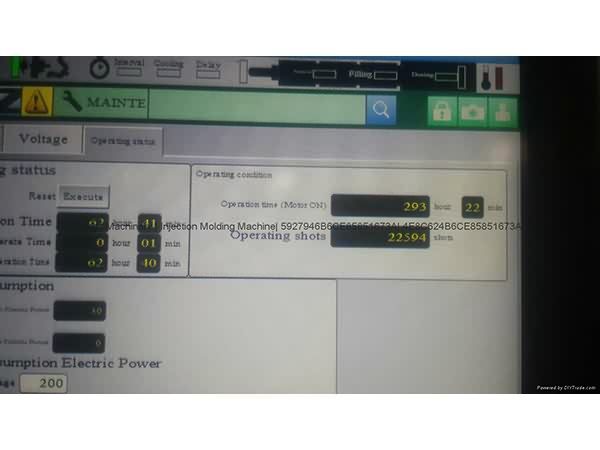

Sumitomo 130t All-Electric Used Injection Molding Machine Video: https://youtu.be/dh8sN_uCzjU Model: SE130EV-C360HP. Year: 2013. Screw diameter: 25/28mm. Injection Speed: 1000mm/s. Tie bar spacing: 510x510mm. 3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

How Importers And Exporters Can Benefit From The Canton Fair

Our firm aims to operating faithfully, serving to all of our consumers , and working in new technology and new machine continually for Hot New Products Sumitomo 130t All-Electric used Injection Molding Machine to Honduras Manufacturer, The product will supply to all over the world, such as: Buenos Aires , Turin , Seychelles , We believe with our consistently excellent service you can get the best performance and cost least goods from us for a long term . We commit to provide better services and create more value to all our customers. Hope we can create a better future together.

Used Hyundai Injection Molding Machine For Sale In Delhi. 650 Ton Capacity. https://www.machinesale.in/Used-Injection-Moulding-Machine

20,000Lb Used Taylor Forklifts For Sale 616-200-4308 for more information go to https://d1a6prx2duc1gy.cloudfront.net/ or phone us at (616) 200-4308. Available Forklifts changes often, contact us for most recent inventory. Go here: https://d26fito5xtoopf.cloudfront.net We also buy and sell forklifts. Capacities from 15,000lb to 100,000lb for sale.

Used Taylor, 20,000lb, Forklifts For Sale 616-200-4308

https://commondatastorage.googleapis.com/usedmachinery/used-large-capacity-forklifts-sale-fork-trucks/index.html

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.