Hot sale Factory Haitian 250t (servo) used Injection Molding Machine for Ghana Manufacturer

Hot sale Factory Haitian 250t (servo) used Injection Molding Machine for Ghana Manufacturer Detail:

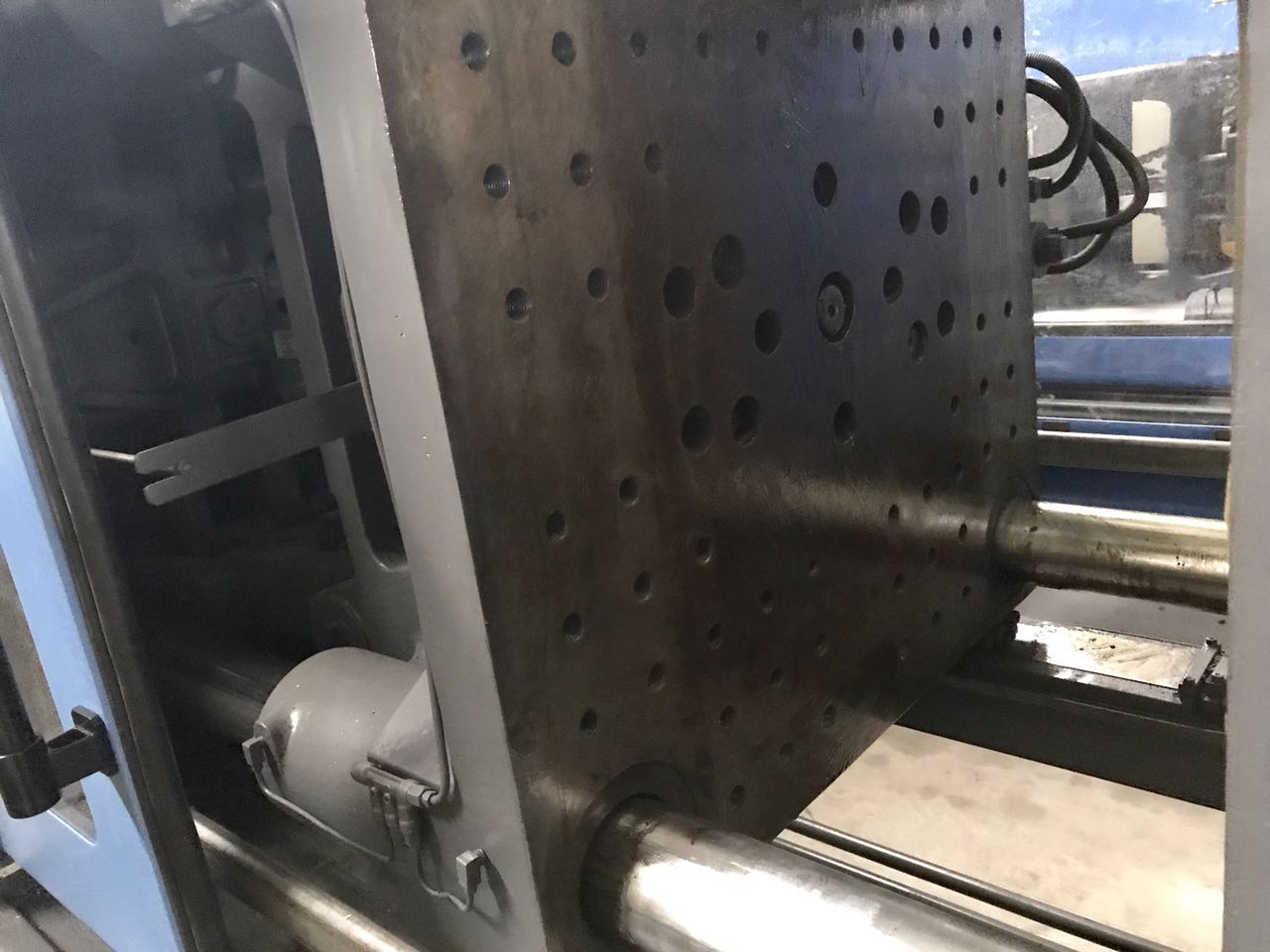

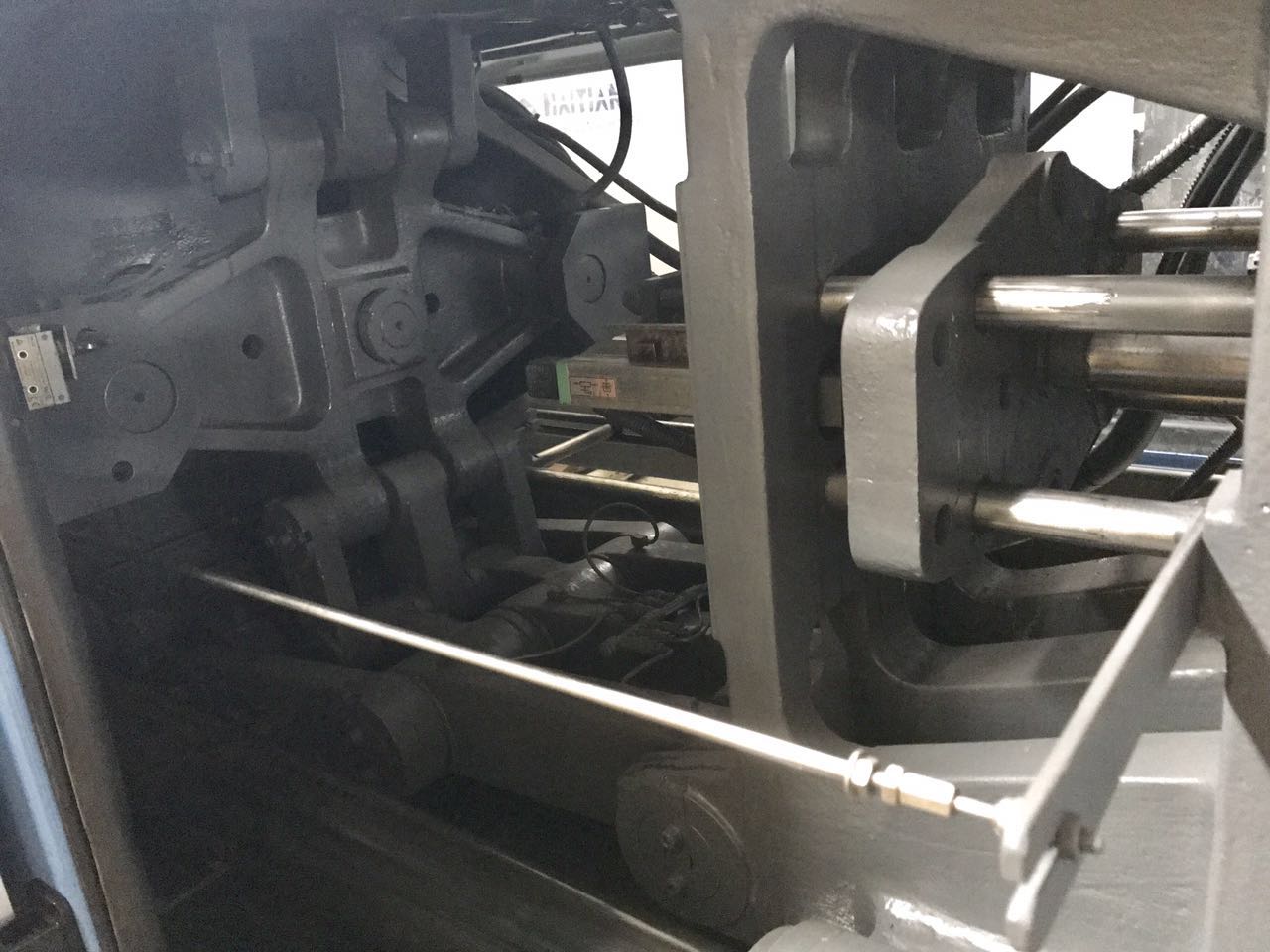

Haitian 250t (servo) used Injection Molding Machine.

Model: MA250.

Year: 2012.

Tie bar spacing: 580x580mm.

Good working condition.

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

We stay with the basic principle of "quality initially, services first, steady improvement and innovation to fulfill the customers" for your management and "zero defect, zero complaints" as the quality objective. To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for Hot sale Factory Haitian 250t (servo) used Injection Molding Machine for Ghana Manufacturer, The product will supply to all over the world, such as: Austria , Bahamas , Tajikistan , Adhering to the management tenet of "Managing Sincerely, Winning by Quality", we try our best to provide excellent products and service to our clients. We look forward to making progress together with domestic and international clients.

Angelelec DIY Open Source Lg-Ns Robot Gripper,Makes a Great Addition to a Small ARM or Mobile Base,Injection Molded Components and Can Use Two Standard Hobby Servos (Not Included) for Open and Rotate: Original Informatique. Pour plus d'informations sur ce produit et à l'achat. S'il vous plaît visitez: https://po.st/CD3zNz Merci!

Angelelec DIY Open Source Lg-Ns Robot Gripper,Makes a Great Addition to a Small ARM or Mobile Base,I

https://www.youtube.com/watch?v=p5dNyD_yO6s

Neck up, always neck up, avoid any problem in the whole process.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.