Hot sale JSWJ1300EIII used Injection Molding Machine to India Factories

Hot sale JSWJ1300EIII used Injection Molding Machine to India Factories Detail:

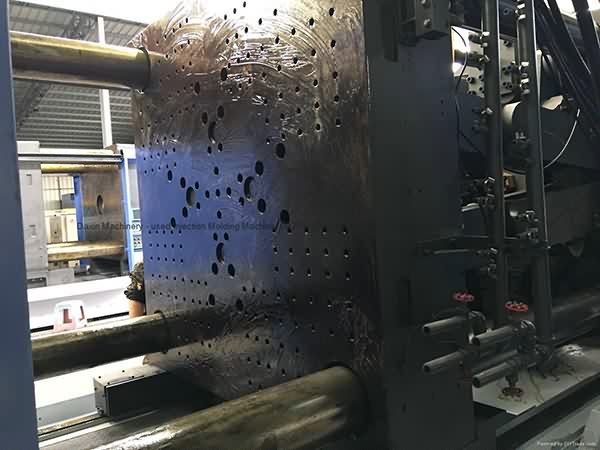

JSW 1600t used injection molding machine.

Model: J1300EIII.

Year: 2008.

Tie bar spacing: 1315x1270mm.

Screw diameter: 120mm.

Machine is in good working condition. Interested customer can visit our warehouse to inspect the machine and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for Hot sale JSWJ1300EIII used Injection Molding Machine to India Factories, The product will supply to all over the world, such as: Chicago , Borussia Dortmund , Malaysia , our qualify products have good reputation from the world as its most competive price and our most advantage of after-sale service to the clients.we hope we can provide a safe, environmental products and super service to our clients from all of the world and establish strategic partnership with them by our professional standards and unremitting efforts.

https://www.CCWDist.com - Retail Display Containers - Our clear plastic retail display containers are a great way to display products, food items and increase sales. If you're looking for plastic containers in FDA approved clear plastic material, we're the container manufacturing experts who can help. Visit our website for more info and to place your order. Or give us a call today at 303-427-9663.

Video shows the process construction of the RTM Light mold the manufacture of the piece.

Produzido por Paulo Camatta, especialista em desenvolvimentos de processos como RTM Light, infusão convencional e com pele de silicone, laminação a vácuo e fabricação de modelos e moldes. Este vídeo foi desenvolvido baseado nos cursos de capacitação operacional que ministrava no CETECOM - Centro Tecnológico de Compósitos até Fevereiro de 2017, com o objetivo de disponibilizar inovações tecnológicas em processos de compósitos poliméricos termofixos.

Este vídeo demonstra resumidamente a contrução do molde e o processo RTM Light - Resin Transfer Moulding assistido a vácuo.

Atualmente Paulo Camatta é Diretor Executivo da CRC Composites, empresa de consultoria e Representação. www.crcomposites.com.br

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.