Hot-selling Mitsubishi 1300t Used Injection Molding Machine Export to Angola

Hot-selling Mitsubishi 1300t Used Injection Molding Machine Export to Angola Detail:

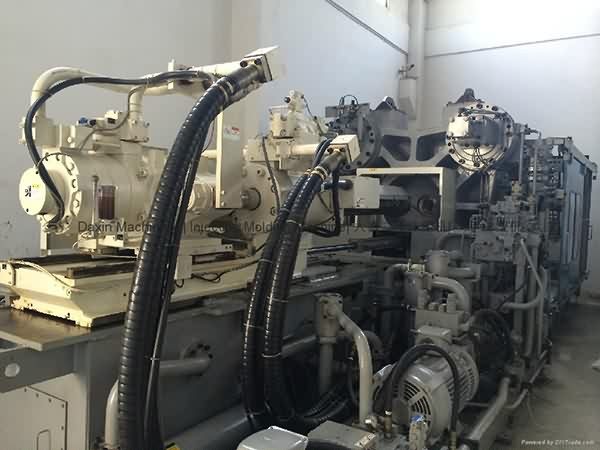

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Screw diameter: 100mm.

Injection volume: 4540cm^3.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Emergence of Injection Molding in Plastic Industry

The really abundant projects administration experiences and just one to one particular provider model make the substantial importance of organization communication and our easy understanding of your expectations for Hot-selling Mitsubishi 1300t Used Injection Molding Machine Export to Angola, The product will supply to all over the world, such as: Austria , Finland , Croatia , Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

It's tailored for the demand of high speed production.

This video is pulp molding machine to produce egg tray, just change the mold in the forming system, this kind of machine also can produce egg carton, egg box, egg tray, fruit tray, bottle tray, paper shoe stretcher, agricultural seedling tray, industrial production packing, paper medical disposable trays etc..

Our website is www.eggtraymachine-sh.com / More information about the machine please send email to: vanilla@eggtraymachine-sh.com vanillashuanghuan@gmail.com / Phone Number: 0086-15673277080 / Skype: vanilla.ling

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!