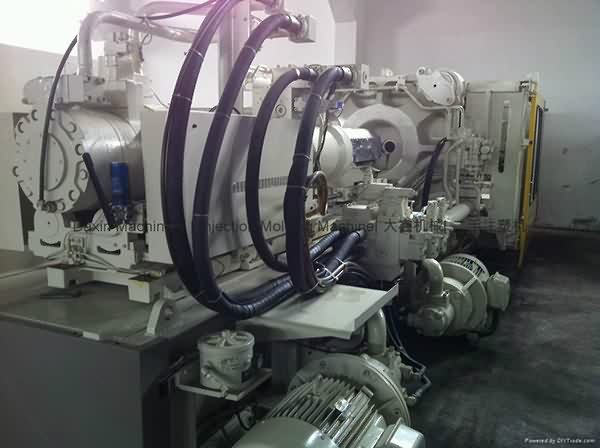

Hot-selling Toshiba IS650GT Used Injection Molding Machine for Colombia Manufacturer

Hot-selling Toshiba IS650GT Used Injection Molding Machine for Colombia Manufacturer Detail:

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT-59A.

Screw diameter: 90/95mm.

Tie bar spacing: 980x980mm.

Year: 2004/2006.

Controller type: V10.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Emergence of Injection Molding in Plastic Industry

continue to enhance, to be certain solution top quality in line with market and buyer standard requirements. Our corporation has a excellent assurance program are actually established for Hot-selling Toshiba IS650GT Used Injection Molding Machine for Colombia Manufacturer, The product will supply to all over the world, such as: Romania , Costa rica , Luxemburg , Each year, many of our customers would visit our company and achieve great business advancements working with us. We sincerely welcome you to visit us at any time and together we will prevail to a greater success in the hair industry.

cartoning machine for Philips bulb automatic box packer автоматическая картонажная машина

Any questions,feel free to contact me.

Email:sales@chinesepacker.com Skype:zhang.tracy6

More information:https://www.chinesepacker.com

Chick here to subscribe us

https://www.youtube.com/channel/UCo4XjYB_mRONyQKah8jbjVw

Introduction:

It is a continuous motion Carton Boxes Packing Machine,which issuitable for the packaging of snack, bottles, vials, noodle,pillow packs, etc.The machine finished running by a series of photo-electro controller to make the machine stability and guarantee the packing quality. It includes cantons in suction and open, products put into, printing batch number, sealing or option hot-glue device. The machine can be single used or linked with Filling Machine, Blister Packing Machine, Shrink Machine, Three Dimensional Packaging Machine to form a production chain.

Feature:

1.International famous brand of electrical component such as PLC touch screen, frequency inverters,etc.

2.Adopt human-machine operation system.

3.Automatically displaying device for trouble, speed and finished products counting.

4.Machine running without pressing if no products or incorrect position of products. And stopping automatically if incorrect position of product into carton after return or no cartons or out of leaflets continuous.

5.No products not suction leaflet, no leaflet not suction carton .

6.Automatic detection and rejection device for lacking blister goods and leaflets.

7.Protecting automatically for overloading.

8.stable performance , operation is easy .

Main Function:

Automatic folding(1-4 folding) and conveying of manual leaflet, automatic maternal categorizing and feeding; automatic paper carton spreading; automatic manual leaflet and material carton packaging, synchronous (3-row) batch number printing, automatic paper carton sealing, automatic waster eliminating.

Main technical parameters:

Encasing speed 50-120 boxes/min

Box Quality requirement 250-350g/m2

Dimension rangeL×W×H (40-250)mm×(20-170)mm×(15-90)mm

Quality requirement 60-70g/m2

Compressed air Working pressure 0.6Mpa

Air consumption 120-160L/min

Power 220V/50Hz

Motor power 1.5kw

Machine dimension(L×W×H) 3100mm×1100mm×1850mm

About Packing:

To ensure our service quality, we will execute the following packaging standards in delivery:

1.All the products before delivery should be tested by assemble and debugging engineer, wiped up and cleaned, then wrapped by stretch film to protect it from moist. The precision part need to flexible package.

2.In addition, without standard tools, manual and other documents, and allow ex-factory confirmation sheet, the machine cannot leave factory All the products will be packed in wooden case. The exported products use plywood case to pack. The foot margin of equipment fixed tightly to make the machine can experience loading and uploading, the upward mark will be posted on the wooden case.

Pre-sales:

According to client specific labeling requirement, supply reasonable machine sketch map,quotation and similar video for client ref first.

During Sales:

1) Depends on client products and labeling position, made reasonable reform base on the standard machine.

2) Repeat 20 ongoing hours testing equipment operation stability .

3) Execute GMP certification for the equipment and materials used in the production process requirement and specification strictly.

After sale:

1. Range experienced senior engineer come to client company for installation .

2. Supply systematic operation training for client workers.

3. Guarantees all equipment (except human factors) within one year, lifetime maintenance sevices.

4. After client use the machine for several years, we can provide a detailed refurbishment program, the original equipment and replacement of hardware and software upgrades.

5. If quality problems arise, the supplier provide technical support and timely supply wearing parts.

call now +919872428844 (whats app available) gautam aggarwal

We are glad to introduce ourselves "prem nath & brothers"as one of the Leading manufaturer of Construction Equipments and Building Material Machineries since the year 1961 . We also take pride in being the largest Export & Import house.

Brick Making Plants,concrete brick machine,bricks machine,cement brick maker,bricks manufacturing plant,bricks manufacturing plant in jammu,bricks manufacturing machinery,bricks manufacturing machinery in punjab,bricks making plant in punjab,v,v,bricks maker plant in punjab,bricks manufacturing plant in kashmir,concrete bricks making video ,cemet bricks manufacturing plant in punjab,concrete bricks manufacturing in punjab,bricks manufacturing ,bricks manufacturing machine,bricks manufacturing plant in india,bricks manufacturing plants

We assure you the Best Quality of our products and after sale-service for years to come.. We hope that you will give us an opportunity for supplying your esteemed organization with the above machinery.

Thanking and eagerly awaiting your valued response.

Website - https://www.machinerymanufacture.com

https://www.flyashbrickmachinery.in

we also export to

Afghanistan Albania Algeria Angola Antigua and Barbuda Argentina Armenia Azerbaijan Bahamas Bahrain Bangladesh Barbados Belarus Beliz Benin Bhutan Bolivia Bosnia and Herzegovina Botswana Brazil

Brunei BulgariaBurkina Faso Burma Burundi Cambodia Cameroon Cape Verde Central African Republic Chad Chile Colombia Comoros Democratic Republic of the Congo Republic of the Congo Costa Rica Côte d'Ivoire

Croatia Djibouti Dominica Dominican Republic Ecuador Egypt El Salvador Equatorial Guinea

Eritrea Ethiopia Fiji Gabon The Gambia Georgia Ghana Grenada Guatemala Guinea Guinea-Bissau

Guyana Haiti Honduras Hungary India Indonesia Iran Iraq Jamaica

Jordan

Kazakhstan

Kenya

Kiribati

Kyrgyzstan

Laos

Lebanon

Lesotho

Liberia

Libya

Macedonia

Madagascar

Malawi

Malaysia

Maldives

Mali

Marshall Islands

Mauritania

Mauritius

Mexico

Federated States of Micronesia

Moldova

Mongolia

Montenegro

Morocco

Mozambique

Namibia

Nepal

Nicaragua

Niger

Nigeria

Oman

Pakistan

Palau

Panama

Papua New Guinea

Paraguay

Peru

Philippines

Poland

Qatar

Romania

Russia

Rwanda

Saint Kitts and Nevis

Saint Lucia

Saint Vincent and the Grenadines

Samoa

São Tomé and Príncipe

Saudi Arabia

Senegal

Serbia

Seychelles

Sierra Leone

Solomon Islands

Somalia

South Africa

South Sudan

Sri Lanka

Sudan

Suriname

Swaziland

Syria

Tajikistan

Tanzania

Thailand

Timor-Leste

Togo

Tonga

Trinidad and Tobago

Tunisia

Turkey

Turkmenistan

Tuvalu

Uganda

Ukraine

United Arab Emirates

Uruguay

Uzbekistan

Vanuatu

Venezuela

Vietnam

Yemen

Zambia

Zimbabwe

Cuba

Nauru

North Korea

Indonesia

Jakarta

denpsar,AFGANISTAN,IRAN,POLAND,MALASIYA

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!