Leading Manufacturer for Chuan Lih Fa CLF-1000T used Injection Molding Machine to Frankfurt Manufacturers

Leading Manufacturer for Chuan Lih Fa CLF-1000T used Injection Molding Machine to Frankfurt Manufacturers Detail:

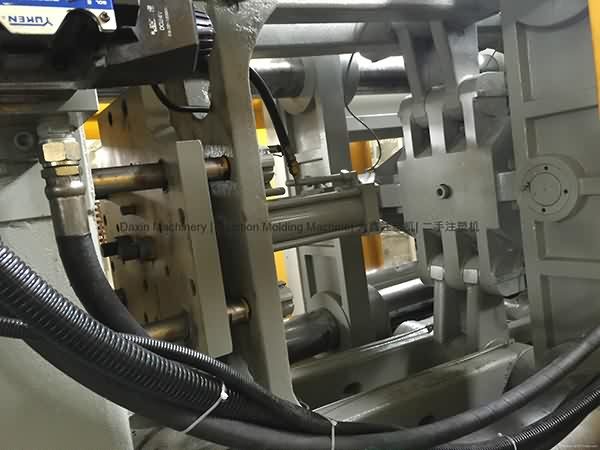

Chuan Lih Fa 1000t used Plastic Injection Molding Machine.

Youtube Video: https://youtu.be/woC2fZ-o8zA

Model: CLF-1000T.

Year: 2006.

Screw diameter: 105mm.

Tie bar spacing: 1050x990mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Precision of Plastic Machining

We constantly function like a tangible group to ensure that we can give you the very best high-quality and also the very best cost for Leading Manufacturer for Chuan Lih Fa CLF-1000T used Injection Molding Machine to Frankfurt Manufacturers, The product will supply to all over the world, such as: Madrid , Singapore , Latvia , We'll initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

more information available: www.uniplastico.com

Produção de lentes com injetora totalmente elétrica modelo EC 350 SXII.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,