Low MOQ for Nanrong 120t used Injection Molding Machine Wholesale to Slovakia

Low MOQ for Nanrong 120t used Injection Molding Machine Wholesale to Slovakia Detail:

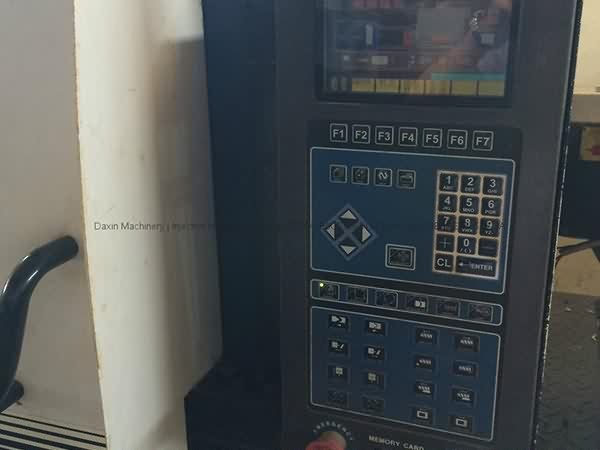

Taiwan Nanrong 120t Used Plastic Injection Molding Machine

Youtube Video: https://youtu.be/Dpld0N3LLpk

Model: 120SA

Tonnage: 120t

Screw diameter: 22mm

Tie bar spacing: 360x360mm

Year: 2006

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou.Interested customers can visit us after Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Plastic Injection Molding: Past, Present and Future

To create more benefit for buyers is our business philosophy; shopper growing is our working chase for Low MOQ for Nanrong 120t used Injection Molding Machine Wholesale to Slovakia, The product will supply to all over the world, such as: New York , Turin , Manchester , we're now looking forward to even greater cooperation with overseas customers based on mutual benefits. We are going to work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

Video shows the process construction of the RTM Light mold the manufacture of the piece.

Produzido por Paulo Camatta, especialista em desenvolvimentos de processos como RTM Light, infusão convencional e com pele de silicone, laminação a vácuo e fabricação de modelos e moldes. Este vídeo foi desenvolvido baseado nos cursos de capacitação operacional que ministrava no CETECOM - Centro Tecnológico de Compósitos até Fevereiro de 2017, com o objetivo de disponibilizar inovações tecnológicas em processos de compósitos poliméricos termofixos.

Este vídeo demonstra resumidamente a contrução do molde e o processo RTM Light - Resin Transfer Moulding assistido a vácuo.

Atualmente Paulo Camatta é Diretor Executivo da CRC Composites, empresa de consultoria e Representação. www.crcomposites.com.br

Problems can be quickly and effectively resolved, it is worth to be trust and working together.