Low MOQ for Toshiba 1300t (wide platen) used Injection Molding Machine for Buenos Aires Manufacturers

Low MOQ for Toshiba 1300t (wide platen) used Injection Molding Machine for Buenos Aires Manufacturers Detail:

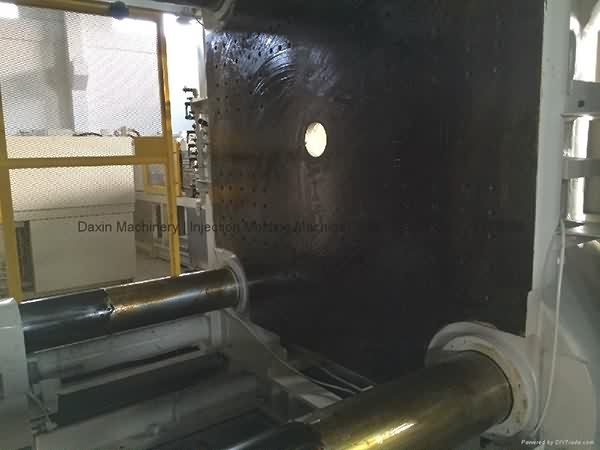

A Toshiba 1300t (wide platen) used injection molding machine for sale.

Model: IS1300DFW-200A.

Year of manufacture: 2004.

Screw diameter: 140mm.

Shot weight:9150g.

Tie bar spacing: 1430x1430mm.

Youtube video: https://youtu.be/hRc5cZvXlFs

Machine has wide platen, it is in good running condition. Interested customer is welcome to visit our warehouse to inspect and test run the machine.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Plastic Injection Molding: Past, Present and Future

go on to boost, to be certain item quality in line with market and buyer standard demands. Our firm has a excellent assurance procedure happen to be established for Low MOQ for Toshiba 1300t (wide platen) used Injection Molding Machine for Buenos Aires Manufacturers, The product will supply to all over the world, such as: Bolivia , Nigeria , Iran , Our mission is to deliver consistently superior value to our customers and their clients. This commitment permeates everything we do, driving us to continuously develop and improve our products and the processes to fulfill your needs.

Angelelec DIY Open Source Lg-Ns Robot Gripper,Makes a Great Addition to a Small ARM or Mobile Base,Injection Molded Components and Can Use Two Standard Hobby Servos (Not Included) for Open and Rotate: Original Informatique. Pour plus d'informations sur ce produit et à l'achat. S'il vous plaît visitez: https://po.st/CD3zNz Merci!

Angelelec DIY Open Source Lg-Ns Robot Gripper,Makes a Great Addition to a Small ARM or Mobile Base,I

https://www.youtube.com/watch?v=p5dNyD_yO6s

https://www.sumitomo-shi-demag.eu

In this application you see how simple Automation can be. A very small 50t machine with an infrared camera Control System. Additional to that you see a servo picker for the sprues and a chute directly integrated into the machine housing. The sprues are regranulated and recylced into the process.

Our other social media channels:

https://www.linkedin.com/company/sumitomo-shi-demag

https://www.facebook.com/sumitomoshidemag/

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.