Manufactur standard Toshiba 1300t (wide platen) used Injection Molding Machine to Suriname Manufacturer

Manufactur standard Toshiba 1300t (wide platen) used Injection Molding Machine to Suriname Manufacturer Detail:

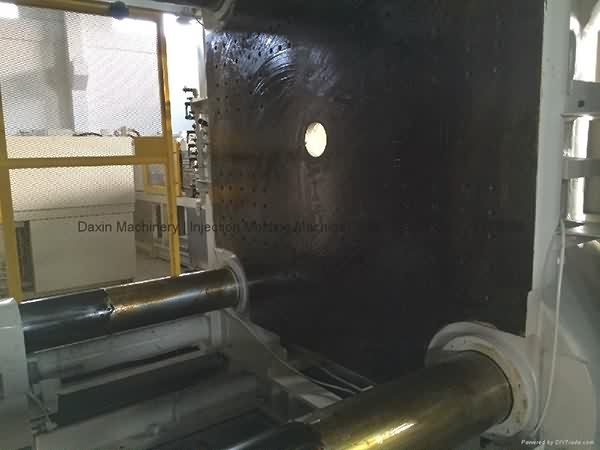

A Toshiba 1300t (wide platen) used injection molding machine for sale.

Model: IS1300DFW-200A.

Year of manufacture: 2004.

Screw diameter: 140mm.

Shot weight:9150g.

Tie bar spacing: 1430x1430mm.

Youtube video: https://youtu.be/hRc5cZvXlFs

Machine has wide platen, it is in good running condition. Interested customer is welcome to visit our warehouse to inspect and test run the machine.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

How Importers And Exporters Can Benefit From The Canton Fair

"Control the quality by the details, show the power by quality". Our enterprise has strived to establish a remarkably efficient and stable team team and explored an effective excellent control system for Manufactur standard Toshiba 1300t (wide platen) used Injection Molding Machine to Suriname Manufacturer, The product will supply to all over the world, such as: Armenia , Portugal , Macedonia , To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

Funcionamiento de una máquina de inyección de plásticos eléctrica de la marca TOYO

Jet Engine Automation Co., Ltd. www.jetrobot.com.tw.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!