Manufacturer for Chen Hsong Super Master SM250TS used Injection Molding Machine to Bahamas Importers

Manufacturer for Chen Hsong Super Master SM250TS used Injection Molding Machine to Bahamas Importers Detail:

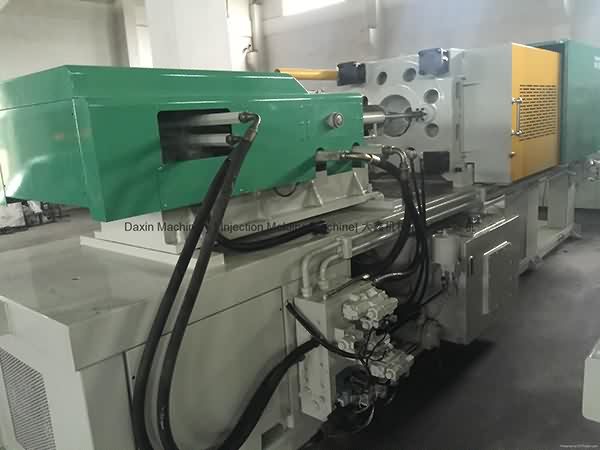

Taiwan Chen Hsong Super Master 250t used Injection Molding Machine for sale

Youtube Video: https://youtu.be/W0oWFc3ZjF4

Model: SM250TS.

Year: 2007..

Screw diameter: 45mm. .

Tie bar spacing: 620x620mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Emergence of Injection Molding in Plastic Industry

While in the past few years, our organization absorbed and digested innovative technologies both equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted for the advancement of Manufacturer for Chen Hsong Super Master SM250TS used Injection Molding Machine to Bahamas Importers, The product will supply to all over the world, such as: Chile , Ukraine , Kazakhstan , We've been adhering to the philosophy of "attracting customers with the best items and excellent service". We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

Cincinnati Milacron VT110 Used Injection Molding Machine, 110 US ton, Yr. 1999, 10 oz., ZAG #7496.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.