Manufacturer of CLF-1000T (servo) used Injection Molding Machine to Algeria Factory

Manufacturer of CLF-1000T (servo) used Injection Molding Machine to Algeria Factory Detail:

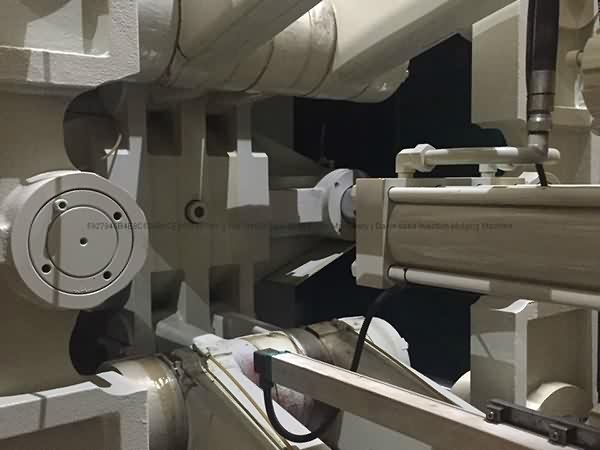

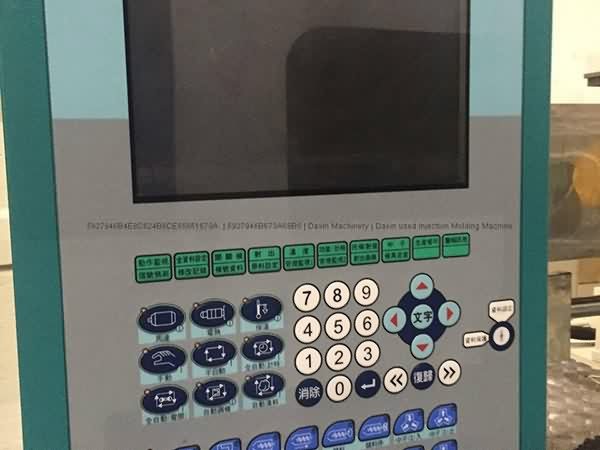

CLF-1000T (servo) used Injection Molding Machine.

Model: CLF-1000T.

Year: 2011.

Screw diameter: 105mm.

Tie bar spacing: 1060mm.

Very good working condition. Interested customer pls visit our warehouse to inspect the machine and test it running under power..

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

To become the stage of realizing dreams of our employees! To build a happier, more united and extra professional workforce! To reach a mutual advantage of our prospects, suppliers, the society and ourselves for Manufacturer of CLF-1000T (servo) used Injection Molding Machine to Algeria Factory, The product will supply to all over the world, such as: Lisbon , Los Angeles , Dubai , We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

Thomas Plastic Machinery, Inc. 812-889-2813 We have for sale a complete stokes vacuum metalizer. It is a full system that was in production before we removed ...

related video: https://www.youtube.com/watch?v=y9HS9sb22Mw

contact us by

support@cnheattransfer.cn / chloe@asia-print.com

Whatsapp / Tel: +86-13728059112

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.