Manufacturer of Haitian 250t (servo) used Injection Molding Machine to Paris Importers

Manufacturer of Haitian 250t (servo) used Injection Molding Machine to Paris Importers Detail:

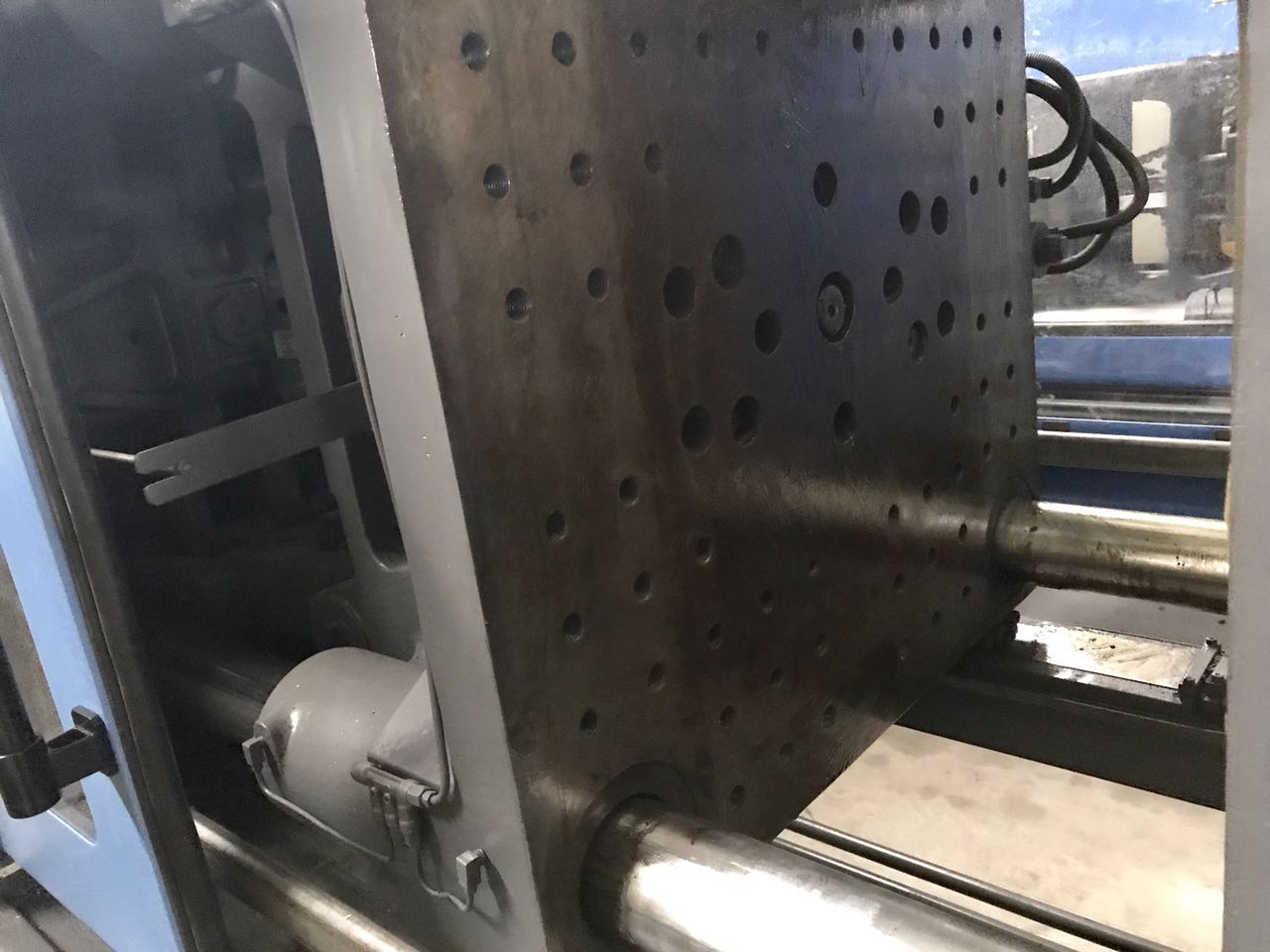

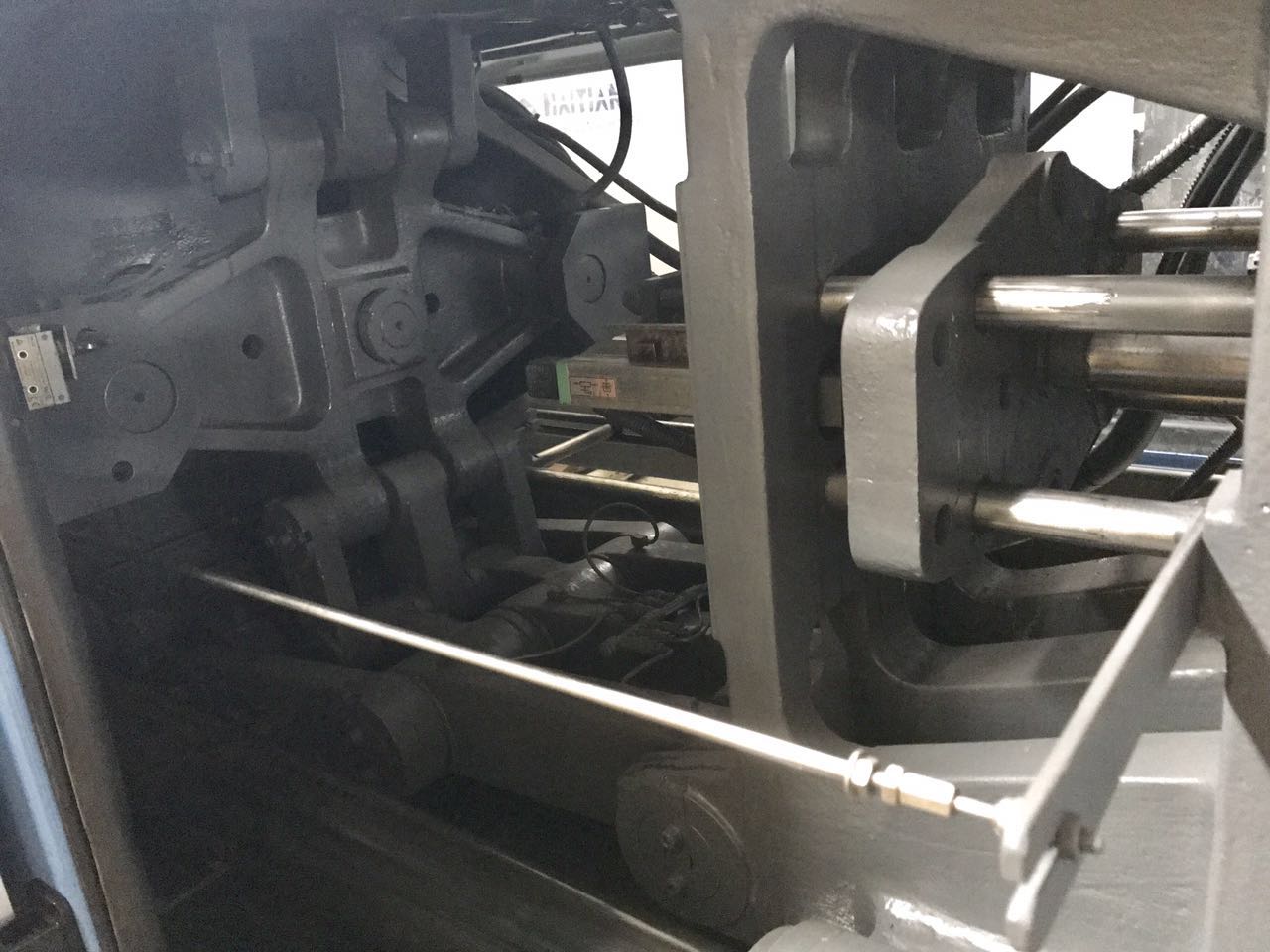

Haitian 250t (servo) used Injection Molding Machine.

Model: MA250.

Year: 2012.

Tie bar spacing: 580x580mm.

Good working condition.

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Plastic Injection Molding: Past, Present and Future

We now have several exceptional workers customers good at marketing, QC, and working with types of troublesome trouble during the creation system for Manufacturer of Haitian 250t (servo) used Injection Molding Machine to Paris Importers, The product will supply to all over the world, such as: America , Mauritania , Finland , We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We are willing to build long-term, friendly and mutually beneficial cooperation with you.

Injection molding of a pen cap connector part from raw materials to finished pen cap part. This video features my new injection molding setup utilizing a 1 ton ...

More information & Pictures: https://www.evermak.com/ITEM.PRO?S=4675&_setlang=EN

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!