Manufacturer of JSW 50t All-Electric used Injection Modling Machine for Croatia Factories

Manufacturer of JSW 50t All-Electric used Injection Modling Machine for Croatia Factories Detail:

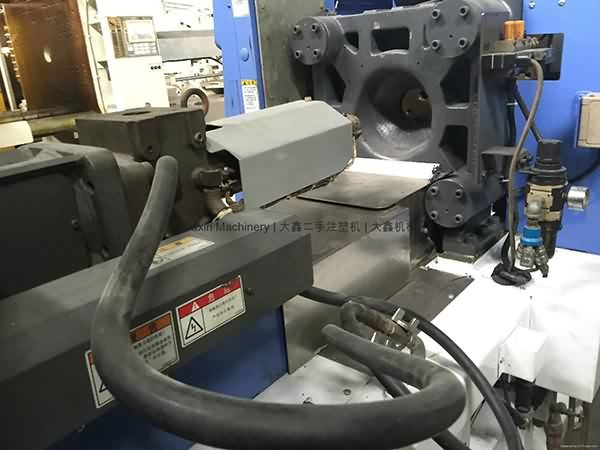

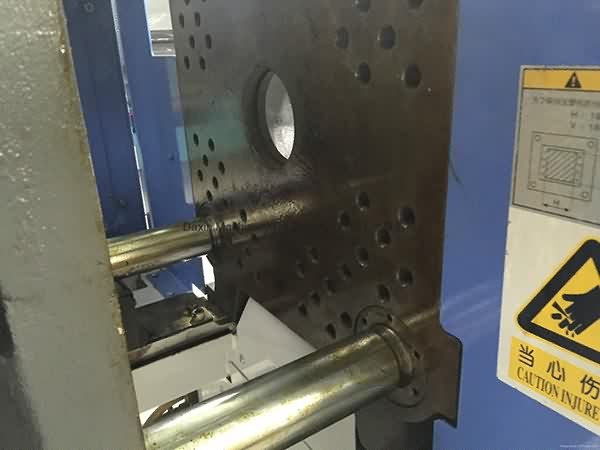

JSW 50t All-Electric Used Injection Molding Machine

Model: JSWJ50ELIII.

Year: 2015.

Screw diameter: 20mm.

Tie bar spacing: 310x31010mm.

Machine is driven by electricity. It is in very good running condition. Interested customer can visit our warehouse to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Emergence of Injection Molding in Plastic Industry

Like a result of ours specialty and repair consciousness, our enterprise has won a superb popularity amid buyers everywhere in the environment for Manufacturer of JSW 50t All-Electric used Injection Modling Machine for Croatia Factories, The product will supply to all over the world, such as: Zimbabwe , Venezuela , Zambia , We provide good quality but unbeatable low price and the best service. Welcome to post your samples and color ring to us .We will produce the goods according to your request. If you are interested in any products we offer, please feel free to contact us directly by mail, fax, telephone or internet. We are here to answer your questions from Monday to Saturday and looking forward to cooperating with you.

Help Removing Water? Massapequa Park, NY Call (631) 888-6080 Open 24/7, Contact Us at (631) 888-6080, or go to our website for more details. Open 24 Hours For Emergencies.

https://westbabylonrestorationpros.com/

Manufacturers of Water Taps in Coimbatore, Tamilnadu, India. Visit www.leotaps.com for more taps and fittings.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.