Manufacturer of Sumitomo 130t All-Electric used Injection Molding Machine Supply to Bangalore

Manufacturer of Sumitomo 130t All-Electric used Injection Molding Machine Supply to Bangalore Detail:

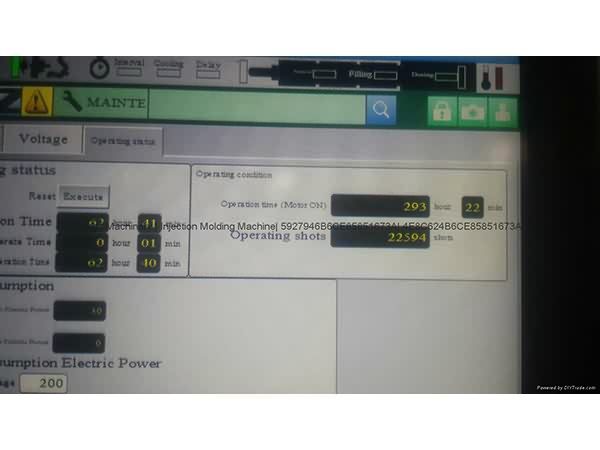

Sumitomo 130t All-Electric Used Injection Molding Machine Video: https://youtu.be/dh8sN_uCzjU Model: SE130EV-C360HP. Year: 2013. Screw diameter: 25/28mm. Injection Speed: 1000mm/s. Tie bar spacing: 510x510mm. 3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Precision of Plastic Machining

Bear "Customer 1st, Good quality first" in mind, we work closely with our prospects and supply them with efficient and professional services for Manufacturer of Sumitomo 130t All-Electric used Injection Molding Machine Supply to Bangalore, The product will supply to all over the world, such as: Dominica , kazan , Zurich , As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to supply our clients sincerely with qualified merchandise, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

You are looking for a used machine? Then you might be interested in this used machinery offer: ENGEL ENGEL ES 200 / 50 Injection Moulding Machine.

MECHANICAL ENGG PROJECT MOTORISED INJECTION MOULDING MACHINE ,THARANGAMBADI,NAGAPATTINAM DIST,TAMILNADU,SOUTH INDIA MOBILE NO 09952895390

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.